Magnetic nanoparticles have a broad application potential in many fields, such as high density magnetic recording media, biomedical technoledgy like hyperthermia, drug carriers and sensors et.al. And it is also very important in the exploring of high performance nanocomposite permanent magnets. Among various magnetic nanomaterials, the chemically ordered L10-phase Co(Fe)Pt NPs have received considerable attention for their large uniaxial magnetocrystal line anisotropy. The controlled preparation of L10-Co(Fe)Pt NPs was previously synthesized by two steps including high temperature solution-phase synthesis of fcc-Co(Fe)Pt, then post annealing above 550 °C after coating (e.g., SiO2 and MgO) or isolating (e.g.NaCl particles) in order to prevent coalesence. This two-step synthesizing method is not only complicated, but it also has a low yield, which severely limited its applications. Therefore, there is still need to find a simpler one-step method to synthesize chemical ordered and dispersing L10–Co(Fe)Pt NPs with monodisperse.

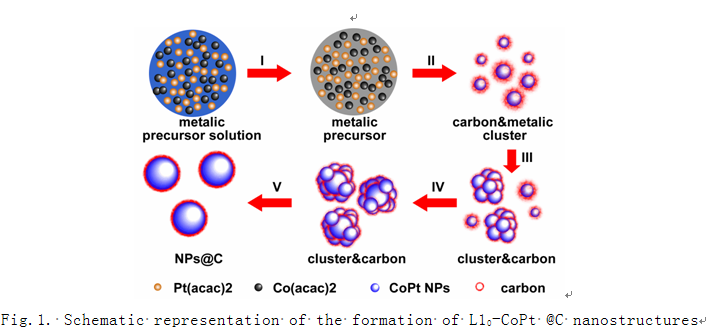

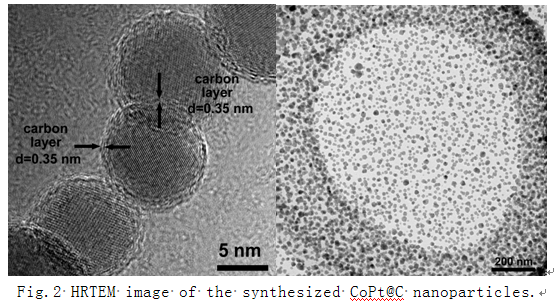

Prof. Juan. Du from Key Laboratory of Magnetic Materials and Devices, Chinese Academy of Sciences, leads a group working on synthesis and magnetic properties of nano materials. Recently, her group developed a one-step solid-phase sintering method for synthesizing chemical and magnetic ordered monodisperse single crystal hard magnetic nanoparticles. Using this method, Co(Fe)Pt@C magnetic nanoparticles not only with a preferred L10/fct phase but also in a size range of 11–15 nm were obtained that has not been achieved using wet chemistry synthetic approaches. For synthesizing Co(Fe)Pt@C NPs with L10 structure, it involved decomposition of Co/Fe(acac)2 and Pt(acac)2 at lower temperature, then grains/clusters nucleation and growth on a substrate, finally recrystallization into single crystal and a phase transition from fcc to fct was accomplished at same time. The growth mechanism has been deeply investigated by transmission electron microscope (TEM). A process of nanoparticles nucleation and growth using this solid phase synthesizing method has been provided as shown below in Fig.1. The synthesized CoPt@C nanoparticles were shown in Fig.2. The prepared L10-FePt nanoparticles have a high coercivity up to 12.2 kOe at room temperature.

Prof. Du’s group has also investigated the effect of reation temperature and protecting atmosphere on the shape of FePt nanoparticles. Nanoflower, worm shape, single particles were obtained by different H2 containing in Ar atmosphere. Nanowire, Cubic, spherical FePt nanoparticles has been achieved by adjusting reaction temperature. [IEEE T. Trans. 49,3307(2013); 50,2102704(2014), chinese patents:201210205994.1]. By using an intermedated precusor Fe(CO)x-OAm, a process of Oriented-Attachment, and Osterwald-Ripening has been observed by TEM, then a precise size control under 1nm was realized by controlling the growth process. [Nanoscale,5,2454(2013),Chinese patent:201210207877.9]. This work was another important process on synthesizing nanostructures with chemical and magnetic ordered phase.

Prof.Juan Du: dujuan@nimte.ac.cn

Research Group Url: http://english.nimte.cas.cn/rh/rd/nmm/nmm_research_interests/

All Images by![]()