A research group led by Prof. GE Ziyi from the Ningbo Institute of Materials Technology and Engineering (NIMTE) of the Chinese Academy of Sciences (CAS) has developed novel giant acceptors with an oxygenated linker, achieving highly efficient non-halogenated-processed organic solar cells (OSCs) with a power conversion efficiency (PCE) up to 20.02%.

This work was published in Advanced Materials.

OSCs feature lightweight, solution-processability, mechanical flexibility, and low-cost fabrication, positioning them as a leading candidate for next-generation photovoltaics.

Conventional OSCs rely on low-boiling-point halogenated solvents to achieve high efficiency, but their high volatility hinders mass production. Although alternative high-boiling-point non-halogenated solvents, such as toluene, o-xylene, etc., are more suitable for scaling up, they often compromise efficiency due to inferior morphology.

Using toluene as a less hazardous solvent, researchers at NIMTE designed a simplified fabrication process for scalable organic photovoltaics.

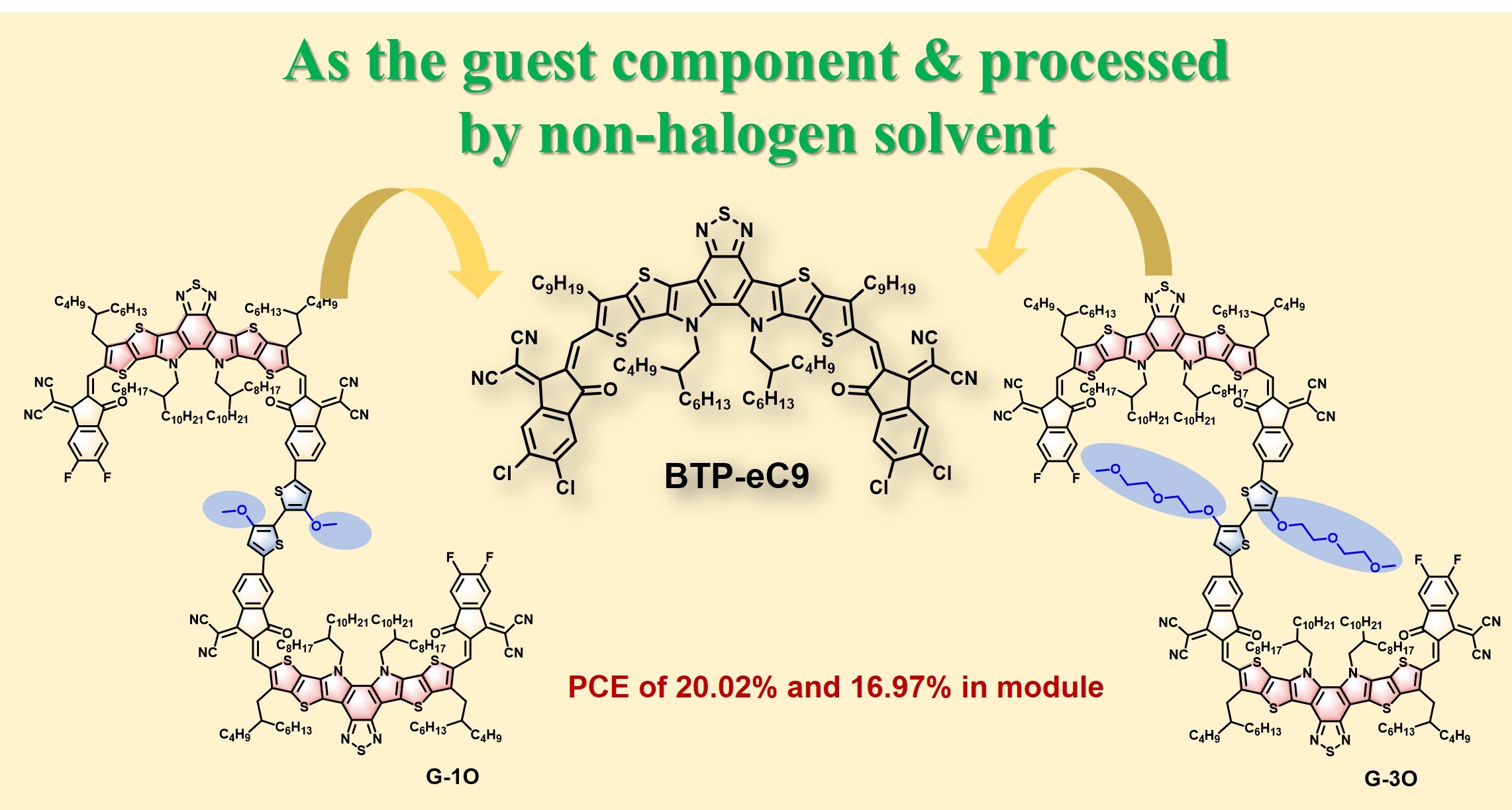

Two giant guest acceptors (oligomerized acceptors), i.e., G-1O and G-3O, featuring distinct oxygenated side chains were introduced into PM6:BTP-eC9 blends, extending crystallization time to suppress excessive aggregation while promoting finer phase separation. These giant guest acceptors retain Y-derivative advantages—precise molecular architectures, excellent photoelectric properties, and robust solution processability—enabling optimized active layer morphology.

Compared to G-3O with its longer oxygenated side chain (which leads to uneven phase separation), the addition of G-1O featuring a shorter chain yields a more homogeneous phase distribution due to enhanced molecular planarity, thereby enhancing charge transfer and reducing voltage loss.

The G-1O-based ternary device achieved a superior PCE of 19.90%, significantly outperforming the G-3O-based device (17.90%).

By applying 100 nm anti-reflection coating (ARC) layer, the performance of G-1O-based ternary device was further enhanced, reaching a PCE of 20.02%.

Moreover, a 15.6 cm² large-area module based on the PM6:BTP-eC9:G-1O system was fabricated. The developed module exhibited a high PCE of 16.97% without dead zone, confirming its scalability and eco-friendly processing advantages.

This work establishes a viable pathway for developing high-performance OSCs using non-halogenated solvents, highlighting their potential for commercial applications.

The chemical structures of the designed guest component and BTP-eC9 (Image by NIMTE)