The State Key Laboratory of Advanced Marine Materials at the Ningbo Institute of Materials Technology and Engineering (NIMTE) of the Chinese Academy of Sciences (CAS) has developed a novel full-ocean-depth-oriented integrated Poly(oxime-urethane) coating, delivering impressive antifouling/anticorrosion performance for marine applications.

The study was published in ACS Nano.

The deep sea is the new frontier. As marine engineering advances into full-ocean-depth operations, equipment now faces a brutal combination of extreme hydrostatic pressure, high salinity, and microbial communities that cause simultaneous fouling and corrosion – a critical threat to long-term durability.

However, conventional multilayer protective systems are prone to interfacial delamination and functional degradation. This fragility renders them inadequate for such harsh conditions. Consequently, achieving synergistic antifouling and anticorrosion protection within a single coating remains a critical and persistent challenge.

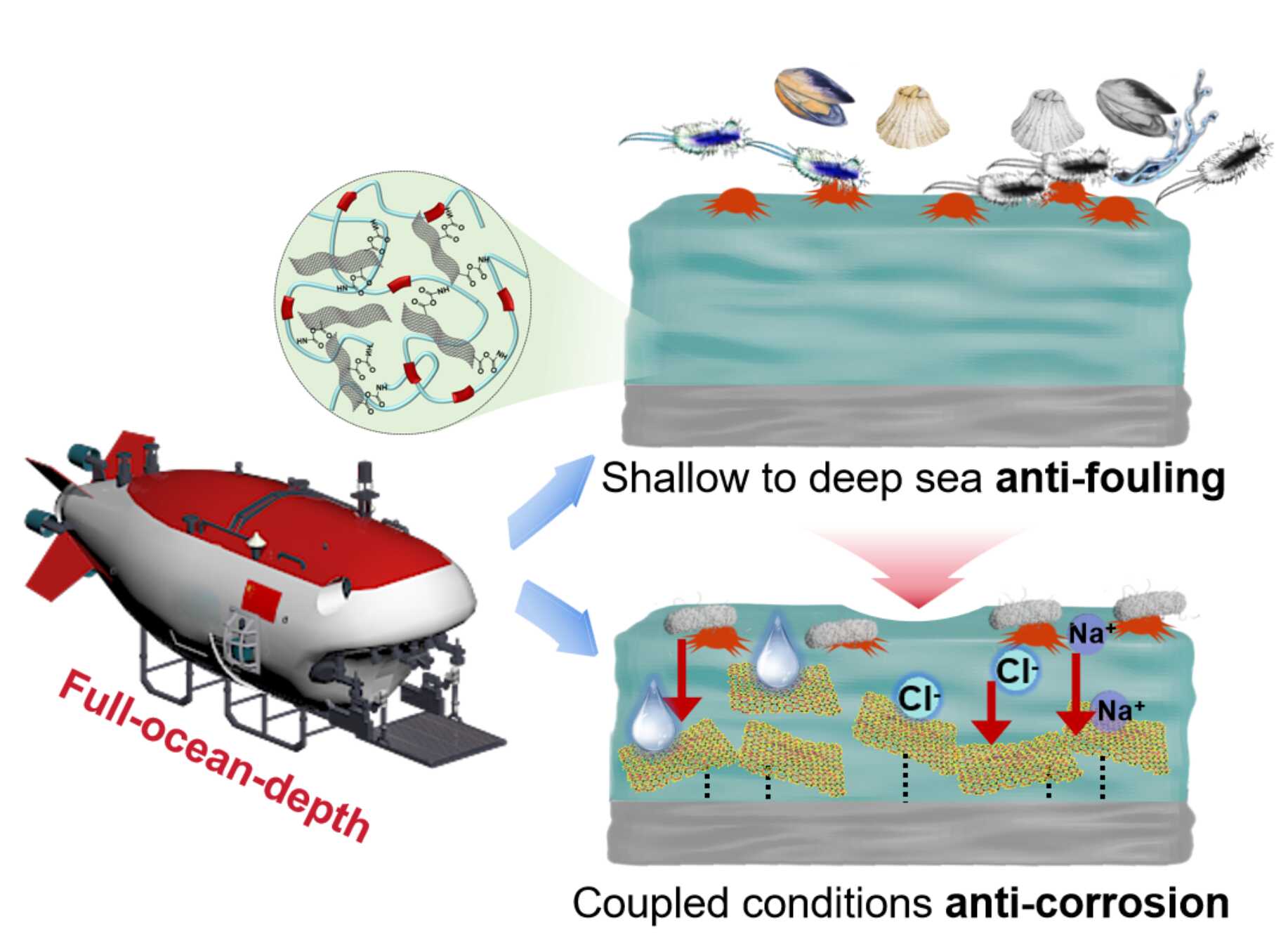

Researchers at NIMTE have recently achieved a breakthrough in full-ocean-depth protective coating technology. Through precise molecular design and nanoscale interfacial engineering, they constructed an integrated antifouling and anticorrosion coating based on poly(oxime-urethane) (PUDF).

This innovative coating combines antibacterial molecules (DFFD) with graphene oxide (GO-COOH) nanosheets to create a unique dual-protection system. The coating exerts its intrinsic antibacterial and antifouling effect by disrupting bacterial purine metabolism and suppressing nucleotide biosynthesis, while the graphene oxide provides a physical barrier that impedes corrosive ions and metabolites. The design provides both active antifouling and strong anticorrosion capabilities, maintaining performance even in extreme deep-sea environments.

Experimental results confirm the coating's full-ocean-depth efficacy: it inhibited the attachment of both macrofoulers in the East China Sea (2 m) and microbial communities in Philippine Sea (7,730 m) over two months. Moreover, it withstood prolonged immersion in a simulated high-pressure (15 MPa), high-salinity, bacteria-rich environment, demonstrating robust anticorrosion capability.

This study sheds light on the synergistic protection mechanism design for high-performance protective coatings in extreme environments.

This work was supported by the Strategic Priority Research Program of the Chinese Academy of Sciences (Nos. XDB1210401, XDC0190000), the Zhejiang Provincial Postdoctoral Research Project (No. ZJ2024069), and the State Key Laboratory of Coatings for Advanced Equipment (Qingdao).

The full-ocean-depth-oriented coating for integrated antifouling and anticorrosion (Image by NIMTE)

Contact

LU Gaungming

Ningbo Institute of Materials Technology and Engineering

E-mail: luguangming@nimte.ac.cn