The Non-crystalline Functional Materials Group from the Ningbo Institute of Materials Technology and Engineering (NIMTE) of the Chinese Academy of Sciences (CAS) has used artificial intelligence (AI) to develop a series of Fe-based amorphous alloys featuring both ultra-high magnetization and ultra-low coercivity. These materials promise to boost the energy efficiency and performance of high-frequency, high-power electronic devices. The study was published in Advanced Functional Materials.

The shift toward higher operating frequencies in modern electronics, reaching into the MHz and GHz ranges, has exposed critical limitations in traditional soft magnetic materials like silicon steel. These materials struggle with escalating core losses, leading to reduced system efficiency, increased heat generation, and potential thermal runaway. This inefficiency is pronounced in high-power applications such as 5G communication, electric vehicles, and industrial power supplies, posing a significant hurdle to achieving more compact, lightweight, and efficient solutions for next-generation technologies.

Fe-based amorphous alloys have emerged as the most promising soft magnetic alloys to address this issue, thanks to the low coercivity (Hc) and core losses. However, their relatively low saturation magnetization (Bs) limits applications in high-power-density devices.

Due to the lack of a clear theoretical link between composition and properties in amorphous alloys, the development of Fe-based amorphous alloys has primarily relied on trial-and-error methods, which has impeded progress in alloy development.

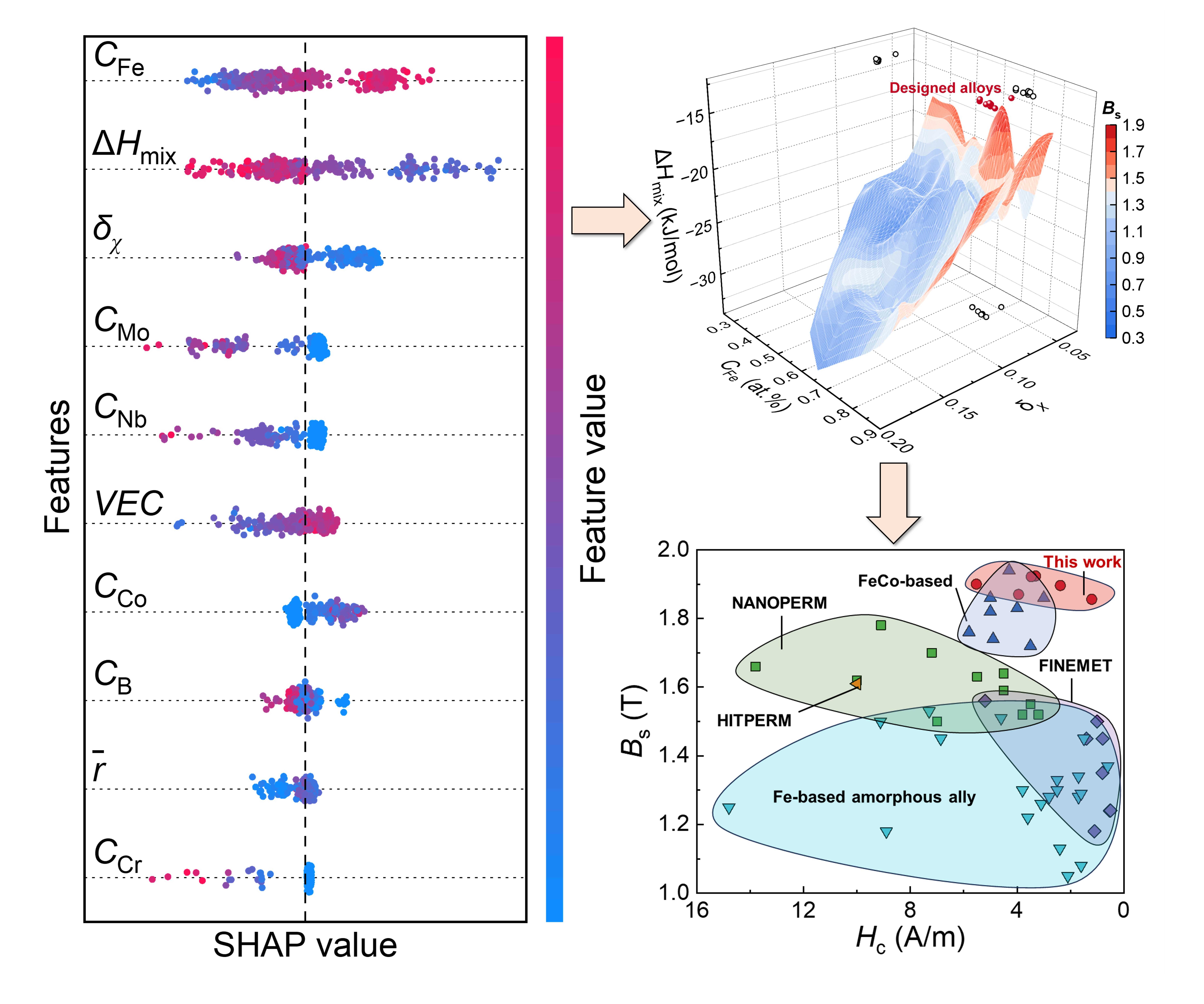

The research team at NIMTE employed machine learning models to predict and optimize the Bs of Fe-based amorphous alloys. The XGBoost model outperformed the other two models, with an R² coefficient above 0.85 and a root-mean-square error below 0.12 T, indicating a superior prediction accuracy.

Through feature analysis, the iron content (above 75 atomic percent), mixing enthalpy (-18.7 to -14 kJ/mol), and electronegativity difference (below 0.07) are identified as key factors driving high Bs while preserving glass-forming ability.

Drawing on these insights, the researchers incorporated cobalt to leverage the Fe-Co exchange coupling effect, designing a range of Fe-based amorphous alloys, including Fe-Co-Ni-Si-B and Fe-Co-Ni-B-P-C. After magnetic field annealing, these alloys achieved Bs values exceeding 1.85 T, some even reaching 1.92 T, and Hc as low as 1.2 A/m, surpassing silicon steel's performance across both metrics.

These advanced alloys hold great application potentials in smaller, lighter magnetic components of electronic systems, contributing to the revolution of next-generation technology requiring high power density and minimal waste heat.

This work was supported by the National Key R&D Program of China (No. 2024YFB3813700), the National Natural Science Foundation of China (Nos. 52231006, 52001319, 92163108, 52271158, 52222105, 51827801, 52201194), the Zhejiang Provincial Natural Science Foundation (Nos. LGF22E010002, LZ22A030001, LR22E010004), the “Pioneer, Leading Goose” R&D Program of Zhejiang (No. 2022C01023), and the Ningbo Key Scientific, Technological Project (No. 2019B10051).

Fig. Fe-based amorphous alloys with high saturated magnetization developed via artificial intelligence (Image by NIMTE)

Contact

WANG Junqiang

Ningbo Institute of Materials Technology and Engineering

E-mail: jqwang@nimte.ac.cn