Prof. WANG Junqiang’s team at the Ningbo Institute of Materials Technology and Engineering (NIMTE)of Chinese Academy of Sciences (CAS), developed a mini-inductor based on amorphous alloys, which can achieve both excellent flexibility and high inductance. The study was published in Advanced Functional Materials.

As a key component of power conversion and signal processing, flexible mini-inductors with high energy density play vital roles in improving equipment performance, reducing energy consumption and realizing equipment miniaturization. Conventional coils are mainly composed of non-magnetic materials, inducing magnetic leakage inevitably. This magnetic flux leakage reduces the inductance density, which makes these inductors unqualified for the low-frequency applications such as DC-DC converters.

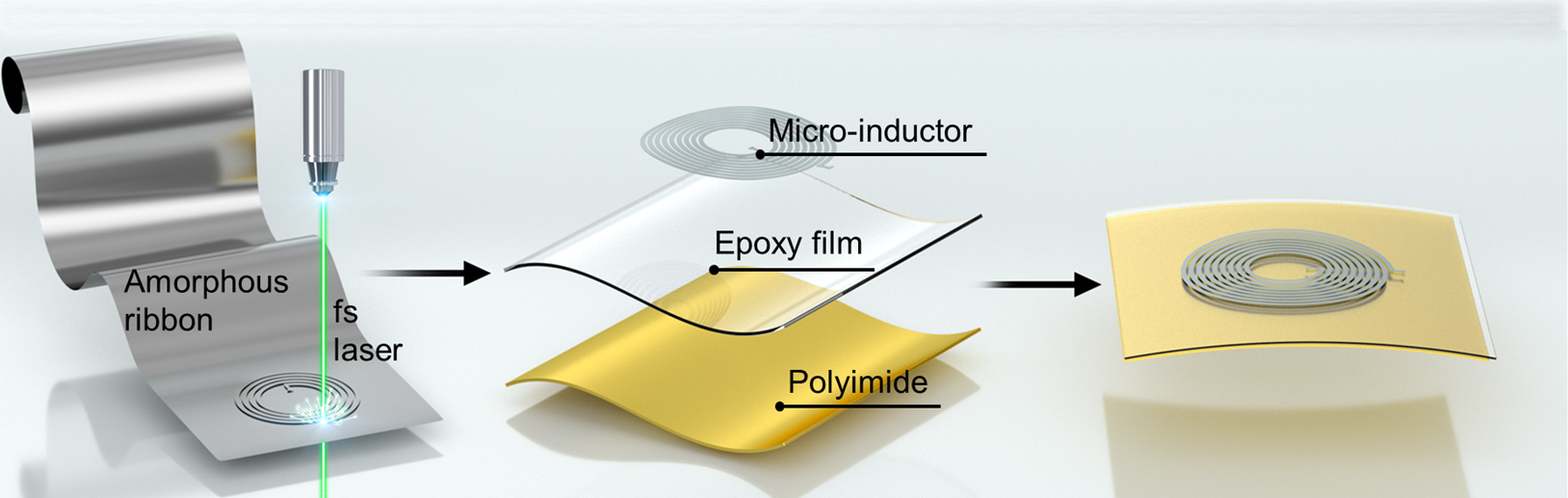

To address this problem, researchers at NIMTE used Fe-based soft magnetic amorphous alloys as coil materials to prepare an amorphous flexible mini-inductor, due to their excellent soft magnetic properties. The high-precision femtosecond laser ablation technology was employed to precisely craft amorphous alloy ribbons without inducing the crystallization of amorphous alloys, while preserved their intrinsic mechanical excellence.

Compared with conventional inductors based on non-magnetic materials such as copper, the developed novel mini-inductor significantly reduces magnetic leakage to less than 10-4 T, greatly minimizing the interference between electronic components.

Thanks to the high permeability of the amorphous alloys, the inductance density of the device increases to about 280-390 nH/mm2, about 10 times higher than conventional planar inductors.

In addition, the amorphous structure endows this flexible mini-inductor with outstanding mechanical flexibility, which can be stretched by 300% of its initial size. After 2500 bending cycles at a 16 mm bending radius, the developed device can remain performance, with only a slight decay (less than 10%) of inductance value and quality factor, indicating its superior stability.

The amorphous flexible mini-inductor can adapt to various bending and folding application environments, due to its flexible design. It can achieve high inductance density in a very small volume to meet the miniaturization needs of thin and light electronic products.

This study not only provides a new application scenario for amorphous soft magnetic alloys, but also sheds light on the material selection and device design of flexible electronics technology.

This work was supported by various projects and programs including the National Natural Science Foundation of China (Nos. 52231006, 52101205, 92163108 and 51922102), “Pioneer and Leading Goose” R&D Program of Zhejiang (No. 2022C01023), Special Foundation of Director of Ningbo Institute of Materials Technology & Engineering (E30101QF01, Grant No. 2021SZKY0309) and Science and Technology Service Network Initiative (No. 2022T3038).

Fig. The design of amorphous flexible mini-inductor using femtosecond laser (Image by NIMTE)

Contact

WANG Junqiang

Ningbo Institute of Materials Technology and Engineering

E-mail: jqwang@nimte.ac.cn