The integrated optimal design can accelerate the iterative design process of complex systems and enhance their overall performance. Through lumping the mechanical, electrical and control parameters into the feedback gain matrix of the dynamic system and solving them efficiently based on the optimal control theory, the flexible manufacturing line can obtain the optimal performance by quick reconfiguration.

However, due to some factors in mechanical structure, driving scheme and control architecture, etc., the feedback gain matrix in complex electromechanical systems has structural constraints, leading to the trouble in solving the optimization problem directly by algebraic Riccati equation (AREs). This limits the application of optimal control theory in the integrated optimization design of electromechanical systems.

The Precision Motion and Intelligent Robotics Research Group at the Ningbo Institute of Materials Technology and Engineering (NIMTE) of Chinese Academy of Sciences (CAS), proposed a structured optimal control method based on parameter space optimization.

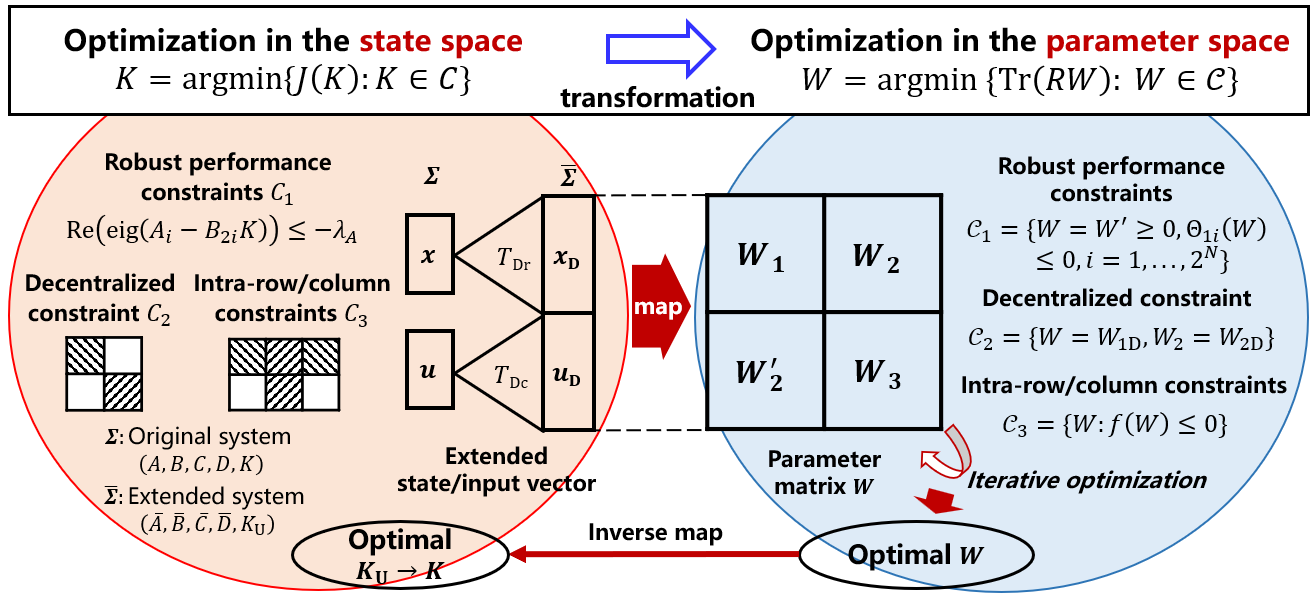

According to the study published in IEEE Transactions on Cybernetics, the feedback gain matrix with intra-row constraints and intra-column constraints was transformed to an unconstrained decentralized feedback gain matrix.

Subsequently, a parameter space including the system state and control input was designed. In this way, the rules for mapping the system dynamics and feedback structural constraints from the state space to the parameter space were proposed, thus transforming the original non-convex structural optimal control problem to a tractable problem which can be efficiently solved with iterative convex programming techniques.

In the numerical process, the constraint supplementary logic was improved for the iterative dual-simplex linear programming algorithm. This allows the generation of multiple cutting planes at a single iteration, which improves the calculation efficiency.

The proposed structured control method shows great potential in the integrated optimal design of rigid-flexible coupling systems, redundant drive systems and underactuated systems.

This work was financially supported by the National Natural Science Foundation of China (Nos. 51875554, U1609206, U2020282) and the Independent Project of Robotics and Intelligent Manufacturing Innovation Institute, CAS (No. C2021001).

Fig. The schematic illustration of the proposed structured optimal control method (Image by NIMTE)

Contact

CHEN Silu

Ningbo Institute of Materials Technology and Engineering

E-mail:chensilu@nimte.ac.cn