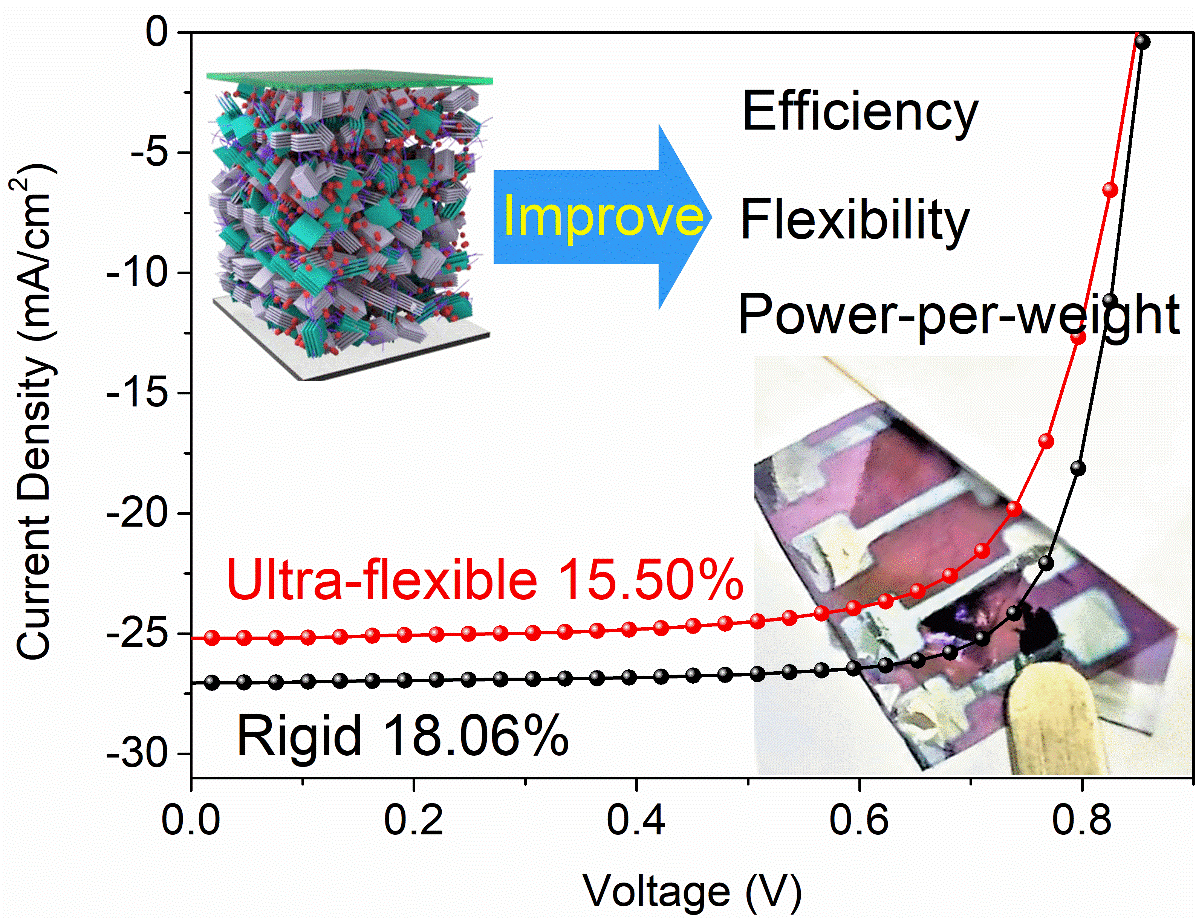

A research group led by Prof. GE Ziyi at the Ningbo Institute of Materials Technology and Engineering (NIMTE) of the Chinese Academy of Sciences (CAS), has made a series of great progress in the research and development of flexible organic solar cells (OSCs). A stabilized power conversion efficiency (PCE) of 15.5% and unprecedented power-per-weight of 32.07 W g-1 at a weight of 4.83 g m-2 were achieved, which are among the best performance reported for OSCs based on ultrathin foils substrate to date. The relevant study was published in Advanced Functional Materials.

As a promising power source for wearable electronic systems, such as electronic textiles and synthetic skin, etc., ultra-flexible and ultra-lightweight OSCs have attracted great attention, thanks to the high absorption as well as good ductility and compatibility. Although the PCEs of OSCs fabricated on plastic solid support substrates have improved rapidly, the development of OSCs based on ultrathin and ultra-flexible substrates is still lagging behind, which greatly limits its inherent advantages in mechanical flexibility.

The researchers at NIMTE found that the ternary strategy can introduce more ductile third component material in the active layer or increasing the amorphous region in the blend, which is beneficial to the dissipation of mechanical stress in the device, thereby achieving robust mechanical stability.

They employed a ternary strategy to obtain high-efficiency ultrathin and ultra-lightweight OSCs, which introduces PC71BM acceptor with high-electron mobility into D18-Cl:Y6 binary system to improve exciton separation and optimize the blend morphology with more amorphous regions. This facile ternary strategy can reduce crystallization and aggregates without decreasing the electron mobility, thus reducing the rigidity and brittleness of the active layer. The increase in the ductility of the active layer faciliated improving the mechanical flexibility of the OSCs, resulting in over 90% retention in the PCE even after 200 stretching–compression cycles.

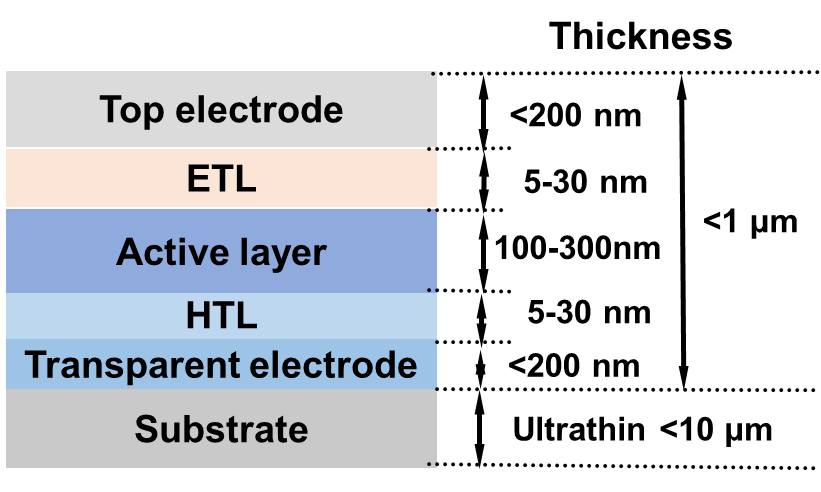

The obtained OSCs with total thickness of less than 3 μm showed a stabilized PCE of 15.5% and excellent power-per-weight of 32.07 W g-1 at a weight of 4.83 g m-2.

Moreover, when stored in a N2-filled glove box, the ternary OSCs performed excellent stability as the PCE retaining over 95% of its initial efficiency after 1000 hours.

This work has provided a facile and efficient approach to fabricate ultraflexible and ultra-lightweight OSCs, which may constitute a major step toward the integration of power supply into malleable electronic textiles.

The study was supported by the National Key R&D Program of China (No. 2017YFE0106000), National Science Fund for Distinguished Young Scholars (No. 21925506), National Natural Science Foundation of China (No. 51773212 and 81903743), Ningbo S&T Innovation 2025 Major Special Program (No. 2018B10055), and CAS Key Project of Frontier Science Research (No. QYZDB-SSW-SYS030).

Fig. The device architecture and J–V characteristics of the ultra-thin flexible OSCs

Contact

SONG Wei

Ningbo Institute of Materials Technology and Engineering

E-mail: songwei@nimte.ac.cn