A research group led by Prof. LIU Jian at the Ningbo Institute of Materials Technology and Engineering (NIMTE) of the Chinese Academy of Sciences (CAS), has developed a novel approach to reduce the phase-transition hysteresis in magnetocaloric La-Fe-Si alloys by microstructural manipulation. The study was published in Acta Materialia.

As environmentally friendly and energy-efficient room-temperature refrigerants, various magnetocaloric materials have attracted increasing attention around the world. However, first-order magnetostructural phase transitions of magnetocaloric materials are inevitably accompanied by large hysteresis, which leads to huge energy loss, reduces cooling efficiency, or even shortens the service-lifespan of materials.

Traditional alloying methods to decrease the hysteresis of magnetocaloric materials inevitably cause a significant reduction of the magnetocaloric effect (MCE).

To address this issue, the research group at NIMTE employed Ce-doping and hydrogenation to achieve the microstructure manipulation of La-Fe-Si magnetocaloric alloys. The comprehensive study on the microstructure evolution was conducted with high angle annular dark field-scanning transmission electron microscope, three-dimensional atom probe and geometric phase analysis.

Owing to the release of internal stress triggered by the uneven distribution of hydrogen atoms, an individual grain of the La-Fe-Si alloy was refined into oriented nanocrystals with diameter of 5–50 nm. The nano-crystallization facilitated the nucleation during phase transition, thus reducing the hysteresis loss by up to 98.8% (from 48.3 to 0.6 J kg-1).

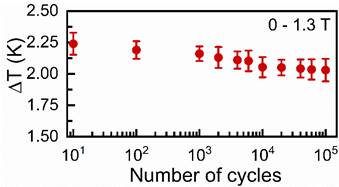

In addition, the itinerant electron metamagnetic phase transition kept an obvious first-order type, leading to a large adiabatic temperature change of 2.03 K (±0.09 K) under a field change of 1.3 T upon 105 magnetic cycles. This indicates that the optimized La-Fe-Si alloy has a large reversible MCE.

Moreover, after hydrogenation, the reversible refrigeration capacity of the La-Fe-Si alloy increased from 78.5 to 89.4 J kg-1 due to the notable reduction of hysteresis loss.

The study has provided a novel perspective to explore nanocrystalline microstructures, and shed light on the development of hysteresis-free magnetocaloric materials exhibiting first-order transition as well as the large-scale application of magnetic cooling technology.

This work was supported by the National Key Research and Development Program of China (No. 2017YFB0702703), the National Natural Science Foundation of China (No. 51971232, 51771218, 52071328), the Ningbo Natural Science Foundation (No. 202003N4028) and Ningbo Science and Technology Innovation 2025 Major Project.

Fig. The magnetocaloric alloy remained adiabatic temperature of 2.03 K in 1.3 T after 105 field cycles (Image by NIMTE)

Contact

LIU Jian

Ningbo Institute of Materials Technology and Engineering

E-mail:liujian@nimte.ac.cn