Researchers at Key Laboratory of Marine Materials and Related Technologies, Ningbo Institute of Materials Technology and Engineering (NIMTE) of the Chinese Academy of Sciences (CAS), have made progress in understanding the surface damage behaviors of ceramic-metal composites. A critical temperature where transitions of wear mechanism occurred was identified for the first time, with the aid of both experimental and theoretical approaches. The findings were published in Acta Materialia.

Due to the increasingly wide range of advanced drilling technique implementation in offshore boring or tunnel boring, the surface damage of drilling tools made of ceramic-metal composites such as WC-Co hard metals or their lightweight substitutes TiC-steel under harsh service conditions have aroused great attention. The surface damage of ceramic-metal composites that triggered by high temperature, oxidation and wear would decrease the durability of tools. Therefore, a comprehensive understanding of the wear mechanism of ceramic-metal composites is a prerequisite for optimizing the properties of tools.

Towards this end, the researchers at NIMTE synthesized a composite containing 50 wt.% TiC and high Mn steel through a powder metallurgy routine. The composite was selected as the model system to study the wear behavior of ceramic-metal composites subjected to variations of temperature and atmosphere, by virtue of computational methods coupled with key experiments.

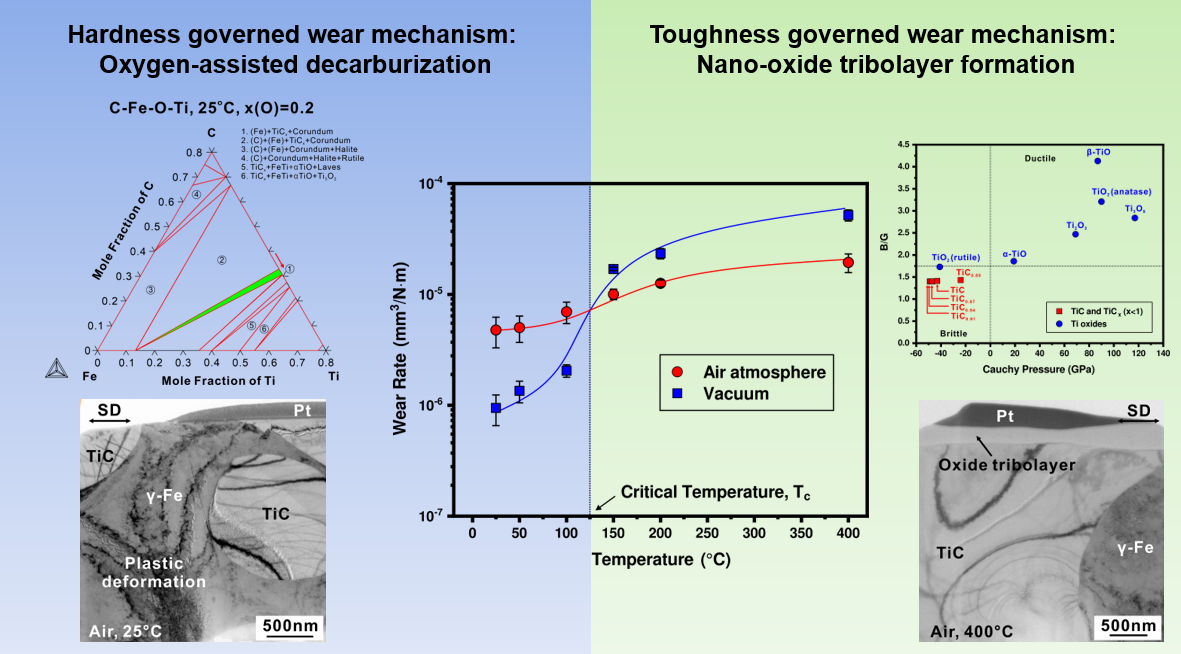

A critical temperature (Tc) of ~125 °C was determined for the wear regime transition. Below this temperature, oxygen-assisted surface decarburization took place on TiC surface and resulted in a reduced hardness thus an increased wear rate, as elucidated by micro-Raman spectroscopy through the CALPHAD (CALculation of PHAse Diagrams) approach. At temperatures above Tc, nanocrystalline oxide tribolayers formed on TiC surface, which enhanced the toughness and refrained the wear loss, as clarified by in-situ TEM observations and first-principles calculations based on density functional theory (DFT).

The micro-mechanisms delineated in this study may provide inspiration for interpreting the wear behaviors of other ceramic-metal composites serving in harsh environments, and may shed light on the future design and manufacture of durable tool materials.

The study was supported by the National Natural Science Foundation of China (No. 51971235), Ningbo 3315 Innovation Team (No. 2019A-18-C) and CAS Pioneer Hundred Talents Program.

Fig. The critical transition temperature of wear mechanisms determined for ceramic-metal composites (Image by NIMTE)

Contact

LOU Ming

Ningbo Institute of Materials Technology and Engineering

E-mail: louming@nimte.ac.cn