The marine functional materials group led by Prof. WANG Liping at the Ningbo Institute of Materials Technology and Engineering (NIMTE) of the Chinese Academy of Sciences (CAS), has successfully implemented the directional alignment of graphene nanosheets in organic polymer protective coatings. This parallel arrangement of nanosheets can give full play to the barrier effect of graphene, thereby enhancing the anticorrosion of organic coatings. The study was published in Chemical Engineering Journal.

Organic polymer protective coating is one of the most extensively employed and effective anticorrosion strategies for engineering and equipment. However, during the long-term service in the harsh marine environment, corrosive media (such as H2O, O2, Cl-, etc.) will have a strong permeability to the organic coating, resulting in the interface peeling of the coating and the serious corrosion of the substrate.

Graphene nanosheets with high aspect ratio can effectively enhance their long-term corrosion resistance due to their excellent barrier properties, good chemical stability and antioxidant properties. In particular, the parallel arrangement of graphene in the resin and the optimization and regulation of the structure have always been the core technologies in this field, which are still in urgent need of revolution.

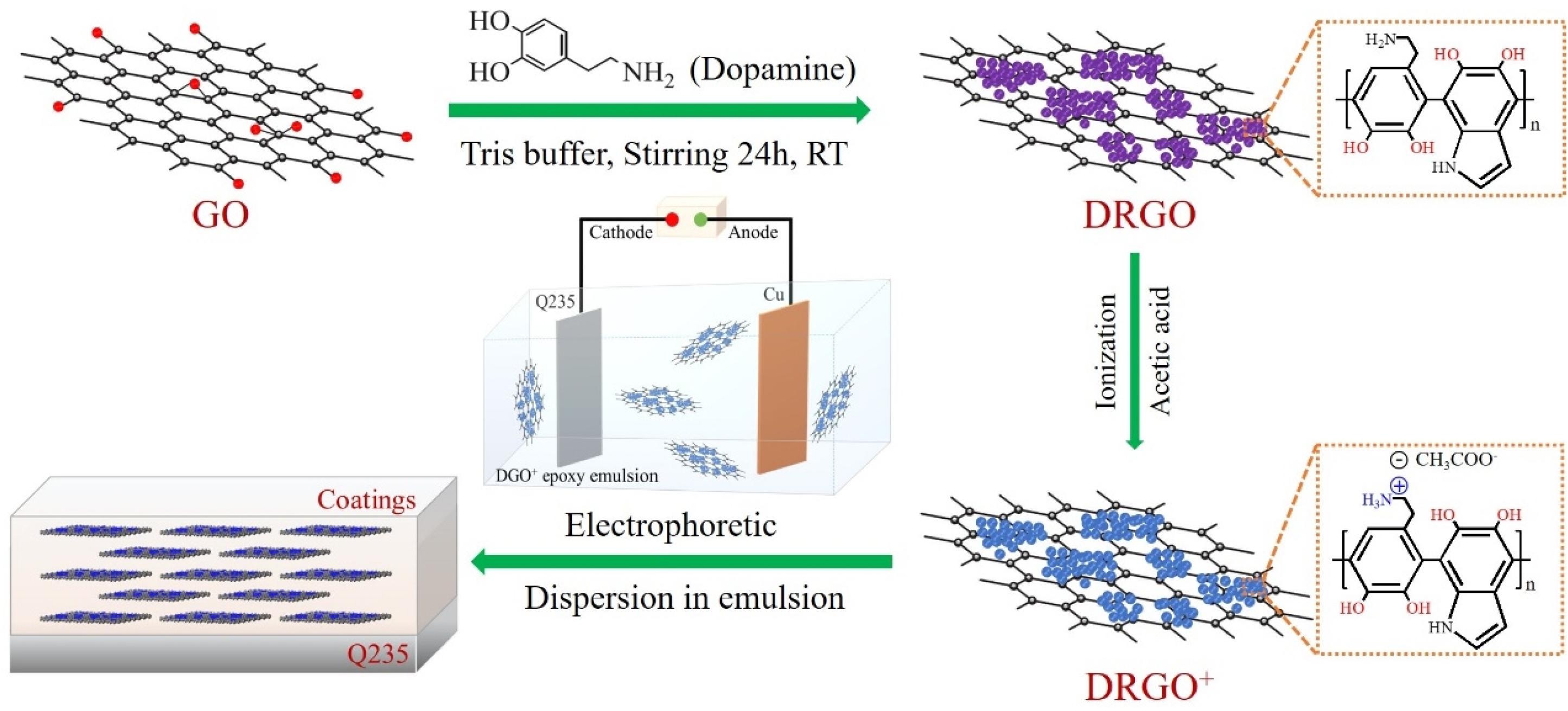

Through simple dopamine oxidative self-polymerization and ionization reaction, researchers at NIMTE successfully obtained a novel cationic dopamine-reduced graphene oxide (DRGO+) nanosheet as a filler for epoxy coating. By virtue of the presence of -NH3+ in dopamine coated on graphene, the DRGO+ nanosheets showed excellent dispersion in water-based epoxy emulsion for more than 45 days without precipitation, and could be self-aligned parallel arrangement in the composite coating under the electric field.

The parallel arrangement of nanosheets immensely improved the barrier effect of graphene, and significantly extended the diffusion path of the corrosive medium, thereby reducing the corrosion rate of the organic coating.

In addition, -NH3+ on the surface of the new cationic DRGO+ nanosheets could adsorb electrons and Cl-, eliminate local galvanic corrosion, and form a dense passivation layer on the steel surface.

This work highlights the potential route for the large-scale fabrication of coatings with extraordinary long-term corrosion resistance.

The study was supported by the National Science Fund for Distinguished Young Scholars of China (No. 51825505), Zhejiang Key Research and Development Program (No. 2019C03093) and Strategic Priority Research Program of the Chinese Academy of Sciences (No. XDA13040601).

Fig. The new cationic DRGO+ nanosheets synthesis and electrophoretic deposition process

Contact

HUANG Ye

Ningbo Institute of Materials Technology and Engineering

E-mail: huangye@nimte.ac.cn