A research group led by Prof. WANG Aiying at the Ningbo Institute of Materials Technology and Engineering (NIMTE) of the Chinese Academy of Sciences (CAS), successfully fabricated dense Cr2AlC MAX phase coatings, and revealed that the oxidation kinetics of Cr2AlC MAX phase coatings follow a two-stage parabolic relationship at 900-1100 °C. The study was published in Corrosion Science (Corros. Sci.).

As one member of the novel family of ternary layered compounds called MAX phases, Cr2AlC was first identified in the 1980s. Benefiting from its high bulk modulus, high thermal-shock resistance, high electrical conductivity, and strong resistance to damage, Cr2AlC has the potential to be a protective coating material in accident tolerant fuel (ATF) systems and other harsh environments. However, Cr2AlC coatings prepared by the traditional PVD techniques show relatively poor oxidation resistance, due to the columnar structure and growth defects.

Through an easy combined arc/sputtering deposition method followed by annealing, researchers at NIMTE prepared dense Cr2AlC MAX phase coatings (purity: 91 wt%) on Hastelloy substrates. The developed coatings were free of columnar structures, including an inner layer and an outer Cr2AlC layer. Therefore, the coatings were able to remain intact even under flowing air for 40 h at 900-1100 °C.

Moreover, researchers further delved into the oxidation mechanism of Cr2AlC coatings at relatively long-term and high temperatures exceeding 1000 °C, which has not been fully examined in previous studies.

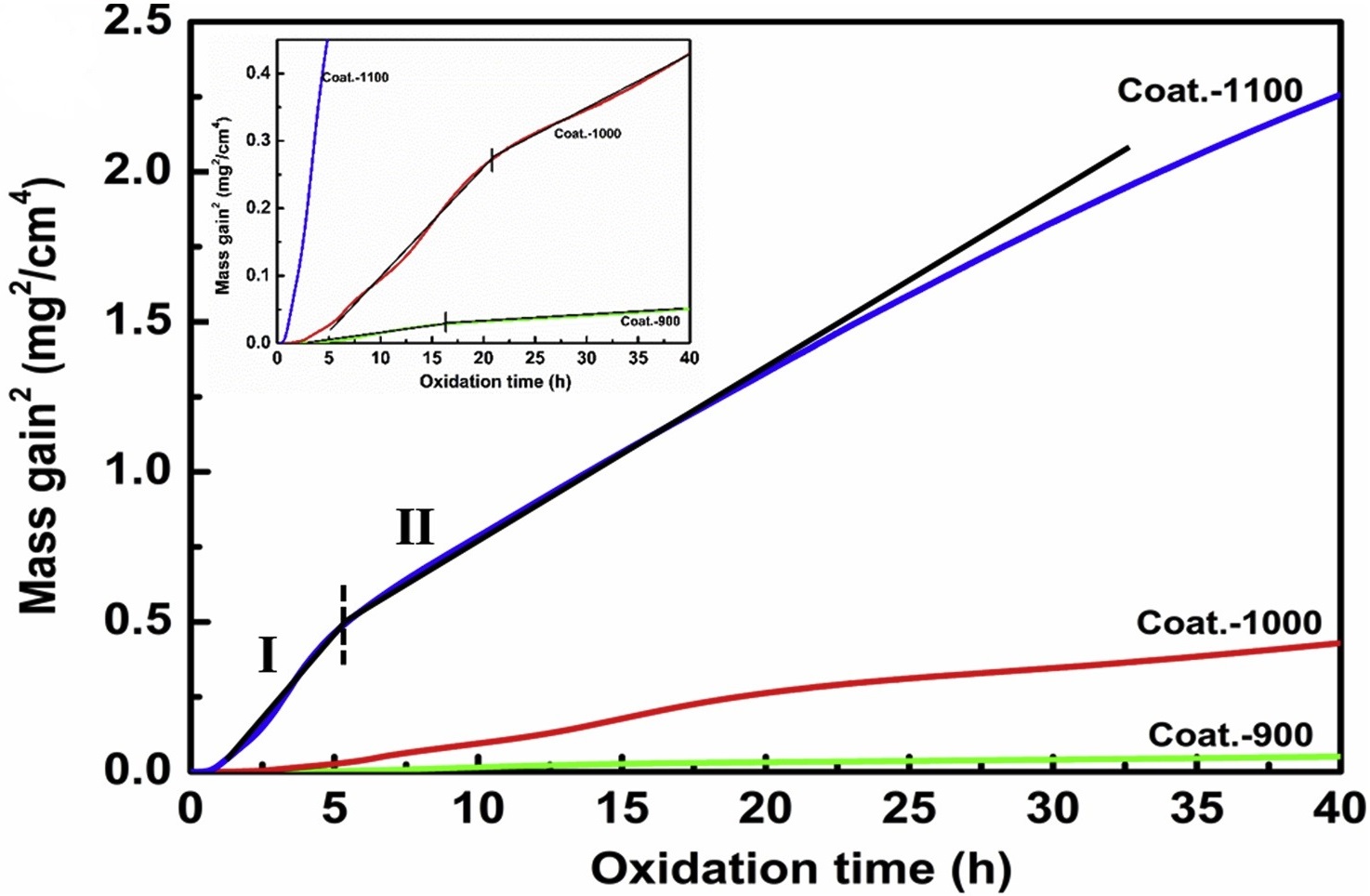

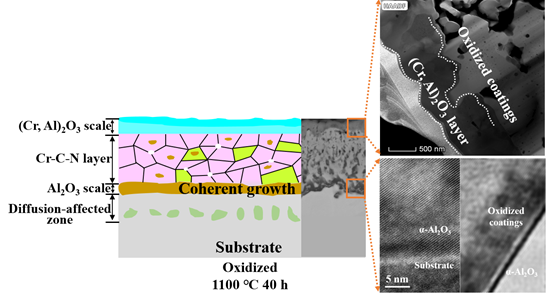

The oxidation behavior investigation of the Cr2AlC coatings at the 900-1100 °C temperature range showed that oxidation kinetics followed a parabolic relationship at each temperature. The parabolic relationship consisted of two stages and the second stage exhibited a slightly lower rate of oxidation. Furthermore, a dense α-Al2O3 layer, exhibiting coherent epitaxial growth with the oxidized coatings and the substrates, was formed during the oxidation at 1100 °C, which provided strong adherence for the oxidized coatings even after 60 cycles of thermal shock tests.

The study illuminated the oxidation mechanisms of Cr2AlC MAX phase coatings at 900-1100 °C. In addition, the novel fabrication method improves the oxidation resistant properties of Cr2AlC MAX phase coatings, thus can promote its applications in high-temperature or other harsh environments.

This work was financially supported by the National Science and Technology Major Project (NO. 2017-VII-0012-0108), National Natural Science Foundation of China (No. 51875555, 51901238), and Zhejiang Provincial Natural Science Foundation (No. LQ19E010002).

Fig.1 The two-stage parabolic oxidation kinetics of Cr2AlC MAX phase coatings (Image by NIMTE)

Fig. 2 The cross-sectional micrographs of the oxidized Cr2AlC coatings at 900 °C for 40 h (Image by NIMTE)

Contact

HUANG Ye

Ningbo Institute of Materials Technology and Engineering

E-mail: huangye@nimte.ac.cn