A research group of Key Laboratory of Bio-Based Polymeric Materials Technology and Application of Zhejiang Province at the Ningbo Institute of Materials and Engineering (NIMTE) of the Chinese Academy of Sciences (CAS) developed a new type of reprocessed thermosets based on acetal exchange chemistry, which possess excellent creep resistance at high temperature (up to 100°C). The study was published in Macromolecules.

Thermosets are widely used in electronic packaging materials, composite materials, adhesives and coatings, due to their excellent mechanical properties, thermal properties, dimensional stability and chemical stability. Nevertheless, thermosets are difficult to recycle because of highly chemically cross-linked three-dimensional (3D) networks.

Introducing dynamic covalent bonds into the cross-linked networks of thermosets can realize the recycling and reprocessing of thermosets like thermoplastics. Meanwhile, dynamic covalent networks also possess various properties, such as the controlled degradation, welding, self-healing, stimulus response, etc. However, the dynamic covalent bonds often lead to the creep and poor dimensional stability of resins, thus limiting their large-scale applications in structural materials.

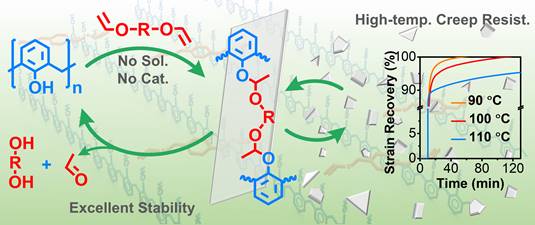

To address this issue, researchers at NIMTE designed an asymmetric acetal structure to achieve thermosets with excellent water resistance, high temperature creep resistance, and mechanical properties. Through one-step “click” cross-linking, reprocessed thermosets were obtained from the phenolic resin and 1,4-cyclohexanedimethanol divinyl ether. The synthesis process was free from catalysts and solvents and small-molecule byproducts.

The asymmetric acetal-type reprocessed thermosets showed excellent creep resistance at high temperature even up to 100°C. Based on the study of small molecule model compounds, acetal exchange at high temperature followed the dissociation mechanism, demonstrating the outstanding reprocessing properties. In addition, the developed thermosets containing asymmetric acetal exhibited high stability in hot water or water/organic solvents. Moreover, their excellent water resistance did not affect their degradation and recycle performances, since the thermosets could be degraded and recovered in a mixed solution of 0.1M HCl water /acetone at 50°C to obtain the original phenolic resin efficiently, which has realized the controlled degradation and recovery of thermosetting resins under mild conditions.

The study provided a facile, green and efficient method to produce readily dual-recyclable (reprocess recyclable and chemically recyclable) thermosets with excellent performance and stability, which promised thermosets containing asymmetrical acetal a bright future in practical applications as recyclable thermosets.

This work was financially supported by the National Natural Science Foundation of China (No. 51773216), the Youth Innovation Promotion Association, CAS (No. 2018335), and the Natural Science Foundation of Zhejiang Province (No. LQ20E030005).

Fig. Preparation of readily dual-recyclable thermosets containing asymmetric acetal and its double recovery process and excellent high temperature creep resistance (Image by NIMTE)

Contact

Li Qiong

Ningbo Institute of Materials Technology and Engineering

E-mail: liqiong@nimte.ac.cn