Amorphous/nanocrystalline soft magnetic materials (ANSMM) exhibit high permeability, low loss, and good frequency stability, which are widely used in electric power, electronic information, intelligent sensing and other industries. Their energy consumption in the production and application process is only 80% of traditional crystalline soft magnetic materials, making them China's key promotion of "double green" energy-saving strategic new materials. However, the current commercially available ANSMM have low saturation magnetization (Bs) and large brittleness after heat treatment. Moreover, the new highBs alloys have problems of low amorphous ability and sensitivity to impurities,

Increasing the diffculty of industrial production.

The ANSMM team in NIMTE used Kissinger method to measure the relaxation activation and confirm the relaxation model. We found that the initial phase beta relaxation can influence significantly the soft magnetic properties of the ANSMM, but the alpha relaxation has little effect. By studying the relationship between viscous dissipation and the domain wall movement speed, we found that the higher the viscous loss energy,

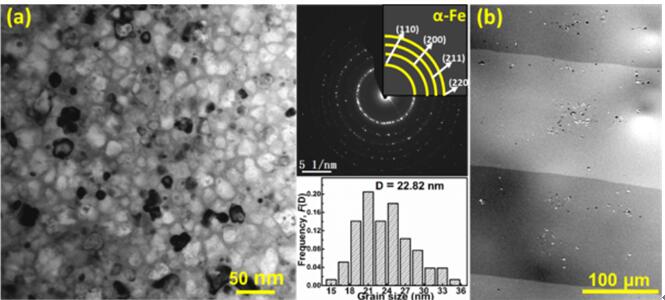

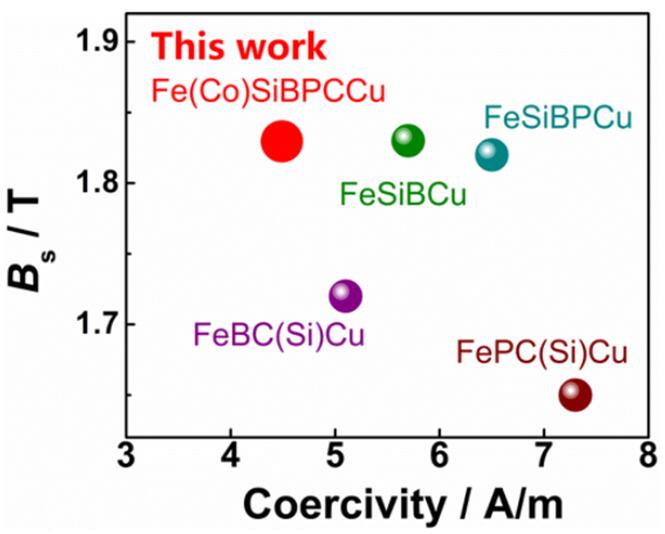

the more difficult the domain wall is to move. Based on the theory of the magnetic coupling interaction, we provided a new way to improve the soft magnetic properties via regulating the viscoelasticity of the alloys. Through cobalt alloying and forming nanocomposite structure, excellent soft magnetic properties such as high Bs of 1.8 T, low coercivity of 4.5 A/m, and high permeability of 21000 at 1 KHz were obtained in the ANSMM. In particular, the performance reaches the international advanced level. Besides, we developed the surface oxygen content control method of molten pool and the melt purification technology, which inhibits effectively the precipitation of impurity phases and thus solve the surface crystallization problem in terms of preparing high-Bs ANSMM. The above research results have enabled us to achieve pilot scale production of high-Bs ANSMM by industrial raw materials.

TEM and magnetic domain of nanocrystalline alloy

Nanocrystalline ribbon

Bs and coercivity of typical nanocrystalline alloys