Cermet layer consisting of metal nanoparticles (NPs) embedded in the ceramic matrix is a key component in solar selective absorbing coatings, and its well-performed optical properties and long-term thermal stability directly determine the solar-thermal conversion efficiency. Generally speaking, the thermal-induced optical degradation of cermet-based coatings is mainly ascribed to the element migration, diffusion and coalescence and/or oxidation of metal NPs. While, it is still a huge challenge for solar selective absorbing coatings to maintain excellent thermal stability, low thermal emissivity and high absorption at elevated temperatures.

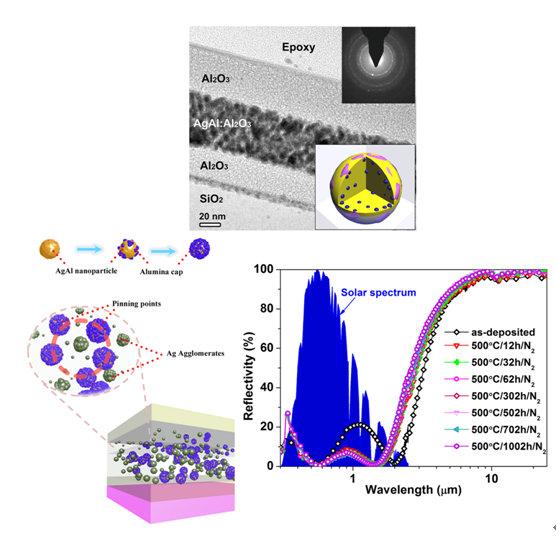

In recent years, the research group of Functional Thin Films & Integrated Devices from Ningbo Institute of Materials Technology & Engineering focused on the design of novel high-temperature tolerable solar selective absorbing coatings. In the previous studies, we demonstrated that AgAl alloy NPs dispersed-Al2O3 matrix could exhibit superior high-temperature antioxidant performance and well-established plasmonic properties. The heat-resistance temperature of AgAl-Al2O3 cermet films was increased to be 500 °C (350 °C for the Ag-Al2O3 counterpart). After annealing for a long period of time (~1000 h) at 500 °C in non-vacuum atmosphere, their optical performance was kept very well (ACS Applied Materials Interfaces 2014, 6, 11550;Applied Surface Science 2015, 331, 285). Then, an optimized AgAl-Al2O3 based solar selective absorbing coating was successfully constructed, possessing a high solar absorption of ~95% and a low infrared emissivity of ~11% @400 °C after annealing at 500 °C for 1002 h in nitrogen ambient (see Fig. 1) (Advanced Materials Interfaces 2016, 3, 1600248).

Fig. 1 Schematic illustration of the thermal enhancement mechanism and the reflectance spectra of the AgAl-Al2O3 absorbing coating

(Image by NIMTE)

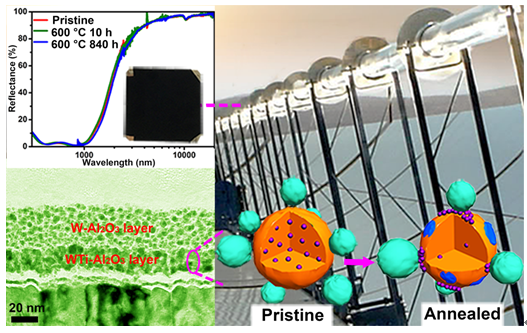

Along with the advance on molten salt (such as 60% KNO3+40% NaNO3) based high temperature solar thermal power generation system, newly-designed selective coatings with sound optical performance and excellent thermal stability are highly desirable for parabolic trough power generation system. In particular, how to obtain excellent thermal stability at 600 °C and suppress the thermal radiation loss is a great challenge. Based on the group’s previous studies, a new WTi-Al2O3 cermet film by introducing Ti to form WTi alloy NPs was developed. Meanwhile, with the help of optical simulation, the target WTi-Al2O3 cermet-based absorbing coating was successfully constructed. After annealing at 600 °C for 840 h in vacuum, the coating exhibited a low thermal emissivity of 10.3% @500 °C and a desirable solar absorptance of ~93%. It is revealed that the surface segregation of Ti solute atoms from the parent alloyed NPs and their partial oxidation to form protective layer could restrain outward diffusion of W element, agglomeration of NPs, and interface structure degradation, in favor of enhancing the thermal tolerance (see Fig. 2) (Nano Energy 2017, 37, 232).

Fig. 2 Reflectance spectra, bright-field cross-sectional TEM image and schematic illustration of the thermal enhancement mechanism of WTi-Al2O3 cermet-based absorbing coating

(Image by NIMTE)

The strategy to improve thermal stability of metal NPs, different from the conventional approach by combining refractory metal NPs with ceramic matrixes, would provide a guidance to create novel alloy NPs systems with great thermal stability for high-temperature applications. We are thankful for the financial supports from the National Natural Science Foundation of China (Grant No. 51302277), the Natural Science Foundation of Zhejiang Province (Grant No. LY17E020012), the key research and development plan of Jiangsu Province (Grant No. BE2015049), and the program for Ningbo Municipal Science and Technology Innovative Research Team (Grant No. 2016B10005).

Prof. Dr. Hongtao CAO: h_cao@nimte.ac.cn

All Images by ![]()