Carbon fiber reinforced thermal polymer (CFRTP) has been widely used in industry applications because of its excellent characteristics, such as high strength-to-weight ratio, high specific modulus, low density, good fatigue resistance etc. Complex structural CFRTP components are always consisted by different parts as the limitation of the mould’s shape and size. Joining the CFRTP parts with metals is an important procedure for its applications.

The laser joining technology has many advantages, such as low thermal effect, non-contacting and high-efficiency etc. The joining mechanism and process between CFRTP and metal laser joining was investigated by the Laser Manufacturing Group of Ningbo Institute of Materials Technology & Engineering (CAS).

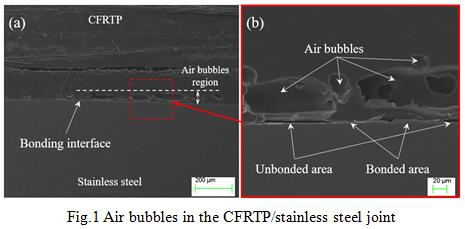

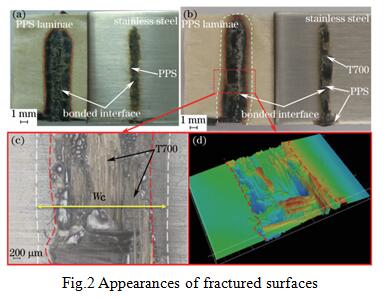

The mathematical model of CFRTP-stainless steel laser joining was established. Relationships between the thermal behaviors and the joining parameters were studied numerically. The CFRTP-stainless steel laser joining experiments were also carried out, and the joining strength, the joint microstructure was tested in detail.(Journal of Materials Processing Technology, 2016, 240:362-369.)

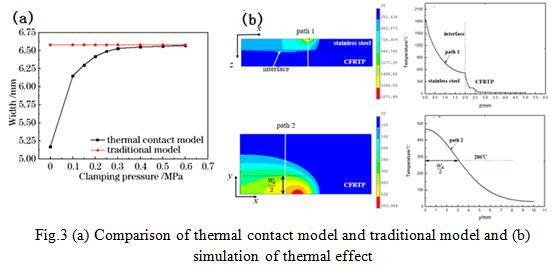

To improve the numerical simulation accuracy of CFRTP-stainless steel laser joining, a three-dimensional model was established by considering the thermal contact resistance. The results showed that the thermal contact model is more consistent with the reality compared with the traditional model. Therefore, the thermal contact model can be used to characterize the influence of clamping pressure on the laser joining quality.(Chinese Journal of Lasers, 2017, 44(4): 0402002. DOI:10.3788/cjl201744.0402002). In additional, through the micro-texture treatment of the metal interface can improve the joining strength significantly. (CN201510014414.4)

This work is supported by NSFC(U1609208), the Youth Innovation Promotion Association Chinese Academy of Sciences (2017343) and the Shenzhen Basic Research Project (JCYJ20150529162228734).

Dr. JunKe Jiao(Professor) :jiaojunke@nimte.ac.cn

All Images by ![]()