Protein and microorganisms absorption on the solid surface is a common but complex phenomenon. Nonspecific adsorption for protein and associated bioadhesion is one of the most significant limitations to biomedical implants, marine ship hulls, water purification and textile industry. Antifouling (AF) coatings have been developed to prevent the settlement of fouling organisms. Traditional biocidal coatings containing heavy metals are detrimental to non-targeted fouling organism and ecologically harmful. Hydrogels are chemically or physically cross-linked 3-dimensional polymer networks with high water content. Owing to the high water content and lack of toxicity hydrogels are environmentally benign antifouling materials. However, most traditional hydrogels are mechanically weak that was limiting their application in antifouling. Considering the limitations of mechanical strength, novel functional hydrogels with high mechanical strength and synergistic prevention of biofouling are greatly desirable.

Recently, the Marine Functional Material Group led by Prof. Liping Wang from Ningbo Institute of Materials Technology and Engineering, CAS, has successfully constructed a series of new nanocomposite (NC) hydrogel with high mechanical strength and excellent antifouling activity through double network strategy and organic-inorganic hybrid nanocomposites.

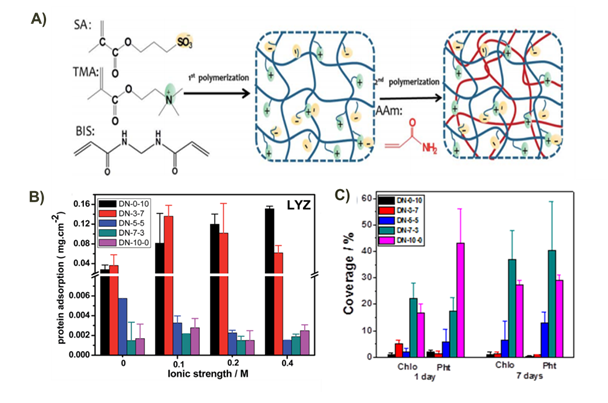

As shown in Fig. 1, a second polyacrylamide (PAAM) network was incorporated into the mixed-charge polymer hydrogel system to form a double network (DN) hydrogel (Fig. 1A). The results showed that the elastic modulus, maximum of compressive stress and strain of DN hydrogels was greatly improved.The maximum of compressive stress of DN-7-3 increased from 0.0387 MPa to 0.4320 MPa, up to 11 times larger than the SN-7-3. The amount of protein absorbed on the DN hydrogel surface was related to the ratio of TMA/SA and the ionic strength (Fig. 1B). The DN hydrogel of DN-5-5 exhibited better protein resistance. The negatively charged hydrogels showed better anti-algae fouling performance than the positively charged and the neutral DN hydrogels (Fig. 1C). (RSC Adv., 2016, 6, 47349–47356).In addition, a tough nanocomposite hydrogels based on quaternized hybranched polyethylenimine (HPEI) nanoparticles. The mechanical strength had a strong dependence with the proportion of the quaternized HPEI nanoparticles. Furthermore, the anti-algae/bacterial assay indicated the nanocomposite hydrogels showed better antimicrobial and anti-algae performance. (RSC Adv., 2016, 6, 60530).

Fig. 1: A) Schematic illustration of the synthetic route for the DN hydrogels. B) Adsorption of LYZon the DN hydrogel surfaces. C) Quantitative coverage of Chlo and Pht on the hydrogels’ surfaces.

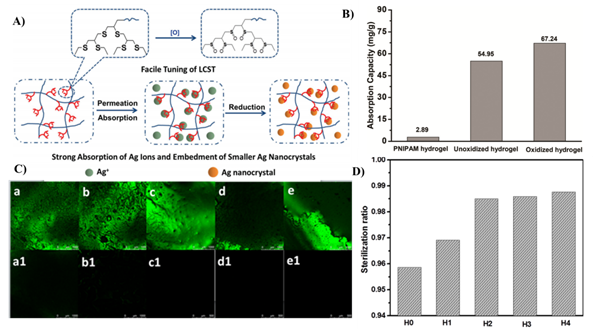

Recently, a series of nanocomposite (NC) hydrogels containing dendritic polythioether architecture were successfully prepared (Fig. 2A). The lower critical solution temperature (LCST) of these hydrogels can be altered in the range of 31.0 oC to 81.1 oC by varying the amount of dendritic monomers and oxidants. The amount and size of the AgNPs embedded in the hydrogel matrix can be regulated by tuning the content of dendritic segments in the polymer matrix (Fig. 2B). (Polym. Chem., 2015, 6, 625).Besides, the hydrogels containing dendrons showed higher AgNPs loading and displayed enhanced retention of nanoparticles. These NC hydrogels showed much better antimicrobial performance for E.coil and anti-algae performance owing to the synergistic prevention of biofouling (Fig. 2C & 2D).(Colloid Polym Sci., 2016, 294, 2021-202).Furthermore, the NC hydrogel based on the thiol/acetyl thioester groups chelating with silver nanoparticles showed better self-recovery performance and antifouling activity. (New J. Chem., 2016, DOI 10.1007/s00396-016-3967-7).

Fig. 2: A)Presentation of oxidation of hydrogel and the formation procedure of Ag nanoparticles in these hydrogels.B)Absorption capacity of Ag+ ions by the pristine PNIPAM hydrogel,the unoxidized hydrogel H3 and the oxidized hydrogel. C)Confocal images of Chlorella and Phaeodactylumtricornutum adhering onto the hydrogels after 24 hours. D)The sterilization ratio of all hydrogel samples.

This work was supported by the National Key Basic Research Program of China (2014CB643305), National Natural Science Foundation of China (51603217), the Innovative Team Projects of Zhejiang Province and Ningbo City (2011R50006; 2011B81001 and 2015B11003).

Dr. Zhixiong Liu: liuzhixiong@nimte.ac.cn

Prof. Liping Wang: wangliping@nimte.ac.cn

All Images by ![]()