All-solid-state lithium batteries, using inorganic solid electrolytes instead of combustible liquid electrolytes, are considered to be the ultimate solution to address the safety issue of currently commercialized lithium ion batteries. However, high energy and power densities are the greatest challenge due to the poor interfacial compatibility between electrodes and electrolytes. The development of stable interfacial structure and intimate contact at electrode/solid electrolyte interface is crucial to realize high-performance all-solid-state lithium batteries.

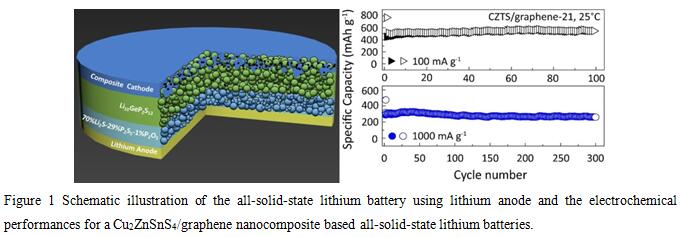

Now in a new study, researchers have designed a new all-solid-state lithium battery, where a solid electrolyte bilayer, i.e. Li10GeP2S12 and 70%Li2S-29%P2S5-1%P2O5, is used, ensuring the compatibility between electrolyte and metallic lithium, as shown in Figure 1. A Cu2ZnSnS4 (CZTS)-based nanocomposite is employed as a promising active material for all-solid-state lithium batteries, showing good interfacial compatibility with sulfide electrolyte due to avoiding high interfacial resistance result from the space charge layer. Meanwhile, graphene serves as electronic conduction network and buffer the volume expansion. The resultant all-solid-state lithium batteries using the Cu2ZnSnS4/graphene nanocomposite exhibit excellent rate capability and cycling stability. At high current densities of 100 and 1000 mA g-1, it can achieves the discharge specific capacities as high as 544.6 and 233.9 mAh g-1 after 100 and 300 cycles, respectively. More information: Hongli Wan et al., “Cu2ZnSnS4/graphene nanocomposites for ultrafast, long life all-solid-state lithium batteries using lithium metal anode”,Energy Storage Materials, 2016, 4, 59-65, DOI: 10.1016/j.ensm.2016.02.004.

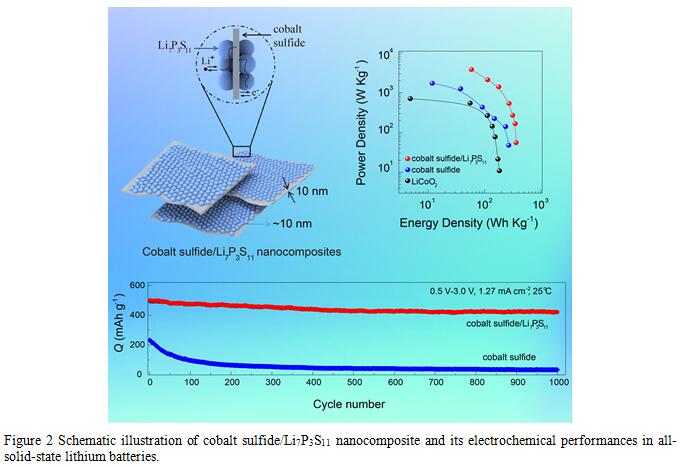

The above work well addresses the interfacial stability between sulfide electrolyte and lithium anode, while intimate contact at the cathode/solid electrolyte as well as low lithium ion transfer kinetics in solid materials are still great challenges. Given all this, a general interfacial architecture was developed by an in situ liquid-phase appraoch, where just 10 nm Li7P3S11 electrolyte particles evenly anchored on cobalt sulfide sheets, resulting an intimate contact interface. This close contact enables the battery to withstand the large stresses and strains during repeated charging and discharging, and eventually lead to significant improvements in energy density and cycle life. As shown in Figure 2, the cobalt sulfide/Li7P3S11 nanocomposite based all-solid-state lithium batteries exhibit reversible discharge capacity of 421 mAh g-1 at 1.27 mA cm-2 after 1000 cycles and 360 Wh kg-1, 3823 W kg-1 at current densities of 0.13, 12.73 mA cm-2, respectively. More information: Xiayin Yao et al., “High-energy all-solid-state lithium batteries with ultralong cycle life”, Nano Letters, 2016, 16, 7148-7154, DOI: 10.1021/acs.nanolett.6b03448.

The authors are grateful for financial support from the Strategic Priority Research Program of the Chinese Academy of Sciences (Grant No. XDA09010201), the National High Technology Research and Development Program of China (863 Program, grant No. 2013AA050906), the National Natural Science Foundation of China (Grant No. 51202265, 51502317) and so on.

Dr.Xiaoxiong Xu:xuxx@nimte.ac.cn

Dr.Xiayin Yao:yaoxy@nimte.ac.cn

All Images by ![]()