In today's world, the electromagnetic (EM) pollution has been becoming more and more serious due to the extensive use of electronic devices and telecommunications.To address this issue effectively, much attention has been paid to developing novel high-performance electromagnetic interference (EMI) shielding materials. The research group led by Prof.Wenge Zheng in Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences (NIMTE, CAS), has devoted great effort to the fabrication of graphene-based materials for high-efficiency EMI shielding over the past few years, and a series of achievements have been published in the international journals (ACS Applied Materials & Interfaces, 2011, 3, 918;ACS Applied Materials & Interfaces, 2013, 5, 2677; ACS Applied Materials & Interfaces, 2013, 5, 11383; Advanced Functional Materials, 2014, 24, 4542; RSC Advances, 2015, 5, 24342;Carbon, 2016, 100, 375; Carbon, 2016, 102, 154;ACS Applied Materials & Interfaces, 2016, 8, 8050). Recently, Prof.Wenge Zheng and his group have achieved some important advances in the structural design of graphene-based materials for excellent EMI shielding again.

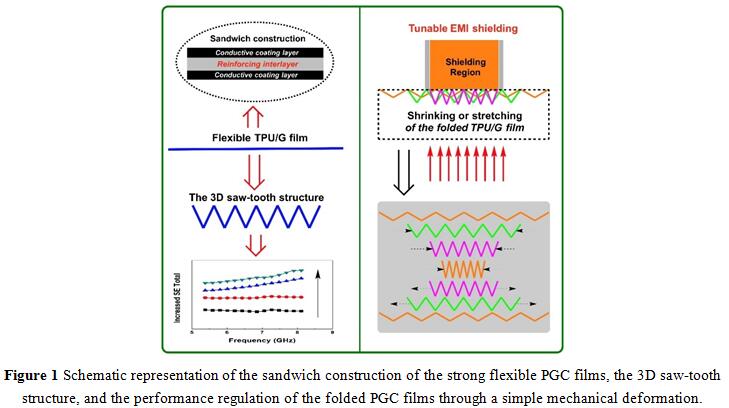

(1) They have demonstrated novel design of mechanically strong flexible polymer/graphene composite (PGC) films with ideal EMI shielding through constructing a sandwich structure consisting of reinforcing interlayer and polymer-based composite with high graphene loading as conductive coating layer, and further investigated the effect of 3D saw-tooth structure on the shielding performance of the flexible PGC films (as shown in Figure 1). The results revealed that the shielding performance could be enhanced very efficiently by saw-tooth folding of the flexible PGC films, and more conductive folded film with smaller included angle plus longer side would result in much greater shielding effectiveness (SE) enhancement along with reduced EM reflection. Besides, this finding realizes the convenient performance regulation of the folded PGC films through a simple mechanical deformation (physically shrinking or stretching the 3D saw-tooth structure), showing promise for tunable EMI shielding. (Carbon, 2017, 113, 55; Chinese Patent:201610850306.5).

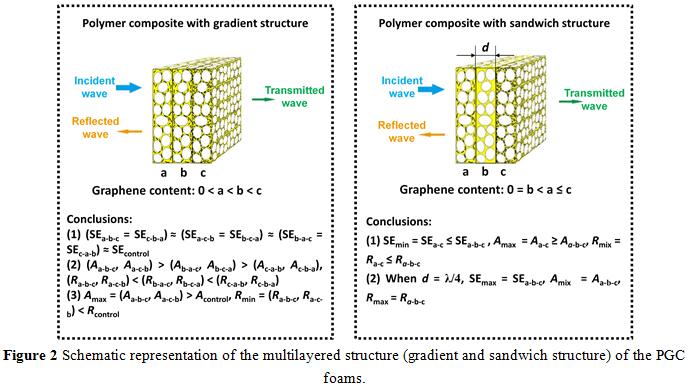

(2) They have investigated the effect of multilayered structure (gradient and sandwich structure) on the shielding performance of the PGC foams (as shown in Figure 2). Multilayered PGC foams were fabricated by stacking single-layered PGC foams together. The arrangement of single-layered PGC foams in different orders could realize the gradient concentration of graphene, which was proved to be a facile approach to enhance the microwave-absorbing property of PGC, rather than their EMI SE. Further sandwiching a wave-transmitting layer between two pieces of PGC foams formed a sandwich structure, by which the SE of the two samples could be significantly improved, which was assigned to the enhanced reflection loss induced by constructive interference, and largely dependent on the thickness of the interlayer d. Particularly, when the values of the d were zero and the quarter of the largest wavelength in the testing frequency range, the minimum and maximum SE could be obtained, respectively. (Composites Science and Technology, 2017, 138C, 209; Chinese Patent: 201610919451.4 and 201610919480.0).

The work is financially supported by National Natural Science Foundation of China (51603218, 51473181, and 51573202), Natural Science Foundation of Ningbo (2016A610269), and China Postdoctoral Science Foundation (2015M570531).