Traditional petrol-based polymeric membrane is difficult to be recycled or degraded after life cycle to cause environmental burden. Bio-based polymeric membrane is expected to solve the problem and shows its great potential in disposable filtration membranes, dialysis membranes and carbon source released membrane. The liquid separation and purification group has made progress in bio-based polymeric membrane synthesis and application. The group have prepared PLA membrane with gradient pore structure (Journal of Membrane Science 2015, 478, 96-104)and modified PLA membranes with heparin and heparin-like surface. e.g. The hydrophilicity and hemocompatibility were improved through dopamine anchoring heparin(Journal of Membrane Science 2014, 452, 390-399), surface APTES anchoring heparin(RSC Advances, 2016, 6, 42684-42692), surface zwitterionization(Journal of Membrane Science 2015, 475, 469-479), surface PEGylation(RSC Advances2015, 5, 107949-107956, ACS Applied Materials & Interfaces2015, 7, 17748-17755)。

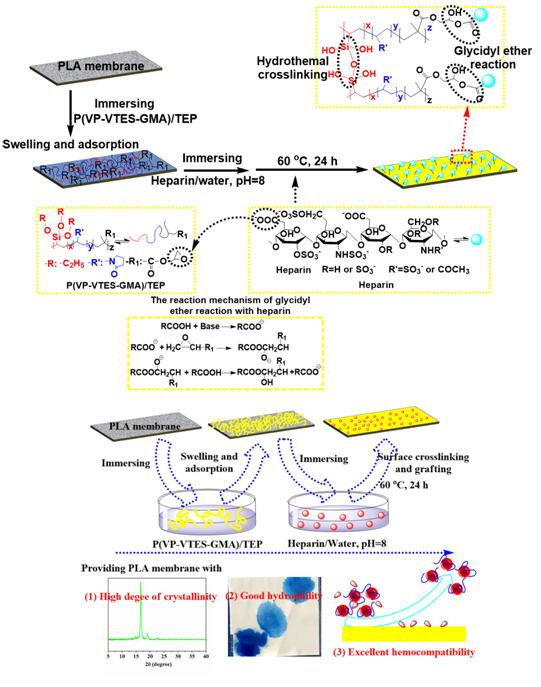

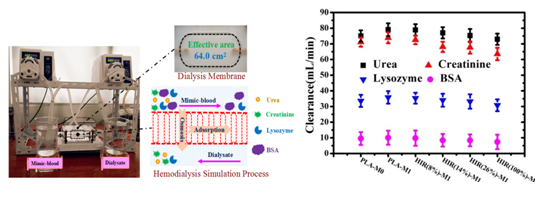

PLA hollow fiber membrane with thin thickness requires good thermal stability, however, the rapid phase inversion is not conductive to the crystallization. The liquid separation and purification group therefore developed an interface crosslinking strategy to induce the crystallization to solve the thermal instability bottle neck. To be specific, P(VP-VTES) copolymer was first synthesized and hydrothermally crosslinked and induced the crystallization of PLA membrane through the swelling and adsorption effect. The specific PLA membrane with χc~37% exhibited excellent thermosstability in aspects of dimension, microstructure, permeability and hemocompatibility under a strict thermal treatment at 100℃ for 5 min (RSC Advances 2016, 6, 20492-20499). To further tune the surface pore structure and distribution, a bio-based pore forming agent β-cyclodextrin was introduced to enhance the pore size and the permeability of PLA membrane. At the same time, the thermal stability and crystallization was improved by the interface crosslinking. (Journal of Membrane Science 2016, 513, 166-176). During the interface crosslinking strategy, reactive groups can be introduced to form the functional platform. A novel precopolymerP(VP-VTES-GMA) was firstly prepared via free radical polymerization. The surface crosslinking of precopolymer containing GMA segments enabled the membrane to anchor heparin through glycidyl ether reaction.The covalent bonding of heparin provided PLA membrane with excellent hemcompatibility, hydrophilicity, heat resistance and dialysis performance as well. (ACS biomaterials science & engineering(DOI: 10.1021/acsbiomaterials.6b00413, Fig 1). To improve the hemocompatibility, The group developed a novel anticoagulant polylactide (PLA) membrane via immobilizing natural hirudin through the hydrogen bonding interaction.The hemocompatibilityof hirudin immobilized PLA membranes were significantly improved due to the affinitive and specific interaction with thrombin, which was verified by blood concretion four items (APTT, PT, TT and FIB).Besides, simulated hemodialysis performance test showed that the clearance of urea, creatinine and lysozyme can reach up to 79 mL/min, 74 mL/min and 34 mL/min respectively, while keeping the high retaining of BSA.(Journal of Membrane Science,Fig 2 and 3)

Fig 1 The interface crosslinking strategy and surface heparinization.

Fig 2 The activated partial thromboplastin time (APTT), the prothrombin time (PT), the thrombin time (TT) variation and the content of the fibrinogen (FIB) transferring to fibrin withdifferenthirudinadsorption concentration.

Fig.3 Simulated hemodialysis system and hemodialysis principle.

The above work is supported by National Natural Science Foundationof China (51473177) and Youth Innovation Promotion Associationof Chinese Academy of Sciences (2014258).

Prof. Dr. Fu Liu:fu.liu@nimte.ac.cn

All Images by ![]()