The raw oil spill accidents and oily wastewater produced in the petrochemical, machinery, leather and textile industries have caused great harm to the ecological environment. In order to protect the ecological balance and human health as well as limited water resources, it is important to separate efficiently the oily wastewater. A composite materials with special surface wettability can simply achieve effective oil/water separation. But most of these materials can only separate oil/water mixtures and are incapable of dealing with oil/water emulsion, especially surfactant-stabilized emulsions. In addition, oily wastewater often contains organic pollutants and harmful microorganism and the water phase can’t be discharged directly into water body system after oil/water separation process.At present, there is little efficient means to further purify the water during the oil/water separation. Therefore, a novel separation material that can simultaneously achieve oil/water emulsion separation and water purification is highly anticipated.

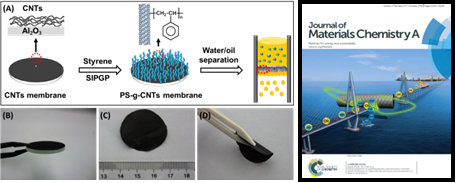

The smart polymer materials group led by Tao Chen Professor from Ningbo Institute of Materials Technology & Engineering, Chinese Academy of Sciences has devoted to the researches on the two-dimensional (2D) polymer nano-composited materials for oil/water separation. Diverse composite materials are fabricated by surface grafting polymer brushes and hierarchical assembly, achieving high-performanceoil/water emulsion separation and water purification. Carbon nanotubes (CNTs) films supported on the porous ceramic substrates are prepared simply by vacuum filtration and then are modified by hydrophobic polystyrene (PS) brushes on both sides by self-initiatedphotografting and photopolymerization(SIPGP). The combination of highly rough surface of CNTs film and polystyrene brushes lead to the formation of super-hydrophobic 2D hybrid film materials (PS/CNTs), which can separate the micron-sized and nanoscale water-in-oil emulsion with high flux and high efficiency (Figure 1, top) (inside cover page in J. Mater. Chem. A, 2014, 2, 15268).

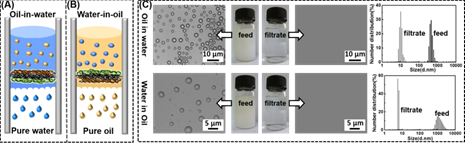

Figure 1. The fabrication of super-hydrophobic PS/CNTs film and its oil/water emulsion separation (top); The selectively oil/water emulsion separation of Janus PDMAEMA/CNTs/PS film (bottom).

Furthermore, super-hydrophobic PS/CNTs film are turn over and transferred to another substrate for grafting poly(2-(N,N-dimethylamino)ethyl methacrylate) (PDMAEMA) brush on the other side by SIPGP method. The resultant Janus PDMAEMA/CNTs/PS film with both hydrophilic and hydrophobic surfaces can selectively separate oil-in-water and water-in-oil emulsions (Figure 1, bottom) (ACS Appl. Mater. Interfaces,2014, 6, 16204). In order to improve the corrosion-resistance of separation materials, 1H,1H,2H,2H-perfluorodecyltriethoxysilane (PFDTS)with small surface energy are grafted on the CNTs films and obtain morphology and flux controllable PFDTS/CNTs hybrid films, achieving effectively rapid oil/water emulsionseparation(J. Mater. Chem. A,2015, 3, 4124). Besides, these PFDTS/CNTs hybrid films possess of good resistance to acid/base, high/low temperature and flame, which provides good basis for improving the practicality of oil/water separation materials.

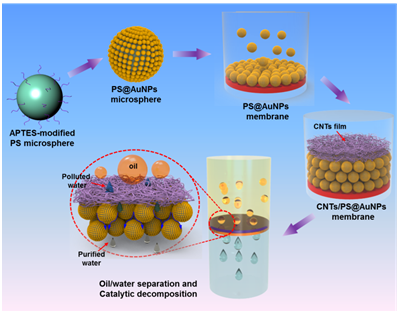

In order to remove effectively the toxic contaminants in oily wastewater, Chen’s group have prepareda novel hierarchical composite membrane materials recently by surface grafting and layer-by-layer assembly methods, realizing simultaneous oil/water separation and water purification.PS hybrid microspheres attached densely by gold nanoparticles (PS@AuNPs) assembled into close-packed microsphere membrane by virtue of vacuum filtration, following by the deposition of hydrophilic CNTs films. The achieved hierarchical membrane possesses superhydrophilic/underwater superoleophobic uppersurface and catalytic underlayer (Figure 2) (J. Mater. Chem. A, 2016, 4, 10810).During the separation process, the oil phase is hindered by upper CNTs films and permeated water phase pass through the membrane along thetortuous channels between hybrid PS@AuNPs microspheres, realizing oil/water separation function. When the water flow through the tortuous channels, the model organic pollutants (nitrophenol and sodium borohydride mixed solution) sufficiently contact with the catalytic AuNPs layers and are catalytically decomposed, achieving simultaneous oil/water emulsion separation and catalytic decomposition of water-soluble organic pollutants for the first time. The multifunctional composite membrane shows a maximum disposal flux as high as about 3500 L m-2 h-1 bar-1and 92.6% catalytic decompose efficiency as well as good catalytic recyclability and durability. Besides, silver nanoparticles (AgNPs) are loaded in the super-hydrophilic CNTs films and the resultant composite film are kill the harmful bacterium in the water phase during oil/water separation (RSC Adv., 2016, 6, 73399). These multifunctional composite materials provide a novel separation technology for industrial wastewater disposal and show great potential in industrialwastewater purification.

Figure 2. The fabrication of underwatersuperoleophobic CNTs/PS@AuNPs composite membrane with a flow-through catalytic decomposition function.

The above work is financially supported by the National Natural Science Foundation of China (No. 51303195, 21304105), Zhejiang Provincial Science Foundation for Distinguished Young Scholars (LR14B040001),Ningbo Science and Technology Bureau (2014A610127,2015A610022), Open Research Fund of Key Laboratory of Marine Materials and Related Technologies (2016Z01) and Zhejiang Nonprofit Technology Applied Research Program (2015C33031).

Prof. Tao Chen: tao.chen@nimte.ac.cn

Dr. LeiZhang: zhanglei@nimte.ac.cn

All Images by ![]()