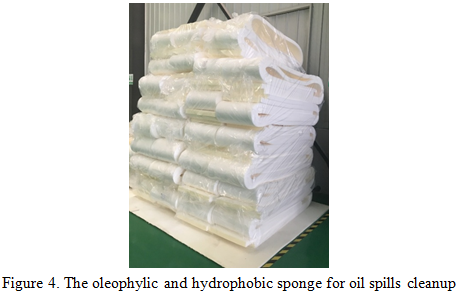

Recently, 2500㎡ production line of the oleophylic and hydrophobic sponge for oil spills clean up has been constructed by the Marine Functional Materials Research Group at the Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences and the industrialization has been realized. Predict by 2016,daily production will reach 25000㎡. Due to the outstanding performance of the product, a strategic cooperation agreement has been signed with oil spills emergency center of PetroChina. And cooperation intentions have reached with Jinshan petrochemical and Shengli oil field.

Oil spills resulting from the frequent accidents of oil exploration, transportation, and storage not only bring great loss of energy resource but also cause adverse impacts to ecosystems. The traditional methods used for oil spills clean up such as oil collection machines, oil dispersing agents, oleiphilus, and oil adsorbing materials can not meet the demands of marine environment protection and resource reuse due to the limitations of low sorption capacity, inefficiency, oil unrecyclable, poor reusability, and secondary pollution. How to efficiently remove and recycle oil spills is still a world challenge.

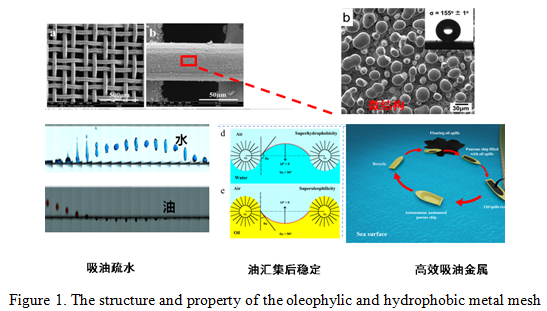

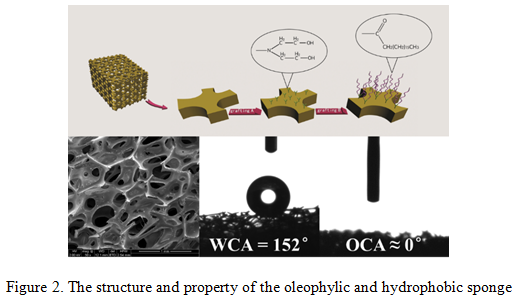

In order to remove and recycle oil spills efficiently, a series of high efficient oil-water separation materials and intelligent oil spills emergency equipment were invented by the Marine Functional Materials Research Group of Zhixiang Zeng and Gang Wang. The oleophylic and hydrophobic materials of sponge (Polymer Chemistry, 2014; Patent:CN201310703409.5) and metal mesh (ACS Applied Materials & Interfaces, 2015; Patent:CN201510392570.4) were fabricated by controlling the pore diameter, micro/nano surface morphology and surface energy (Chemical Communications, 2013; ACS Applied Materials & Interfaces, 2014;RSC Advances, 2015) which can efficiently remove and recycle the light oil (oil spills,gasoline,diesel) on the water and heavy oil (chloroform) under water. Super hydrophilicity and under-water super oleophobicity cellulose sponge was designed for oil/water emulsions separation (Green Chemistry, 2015; Patent: CN201410778473.4). In addition, high corrosion-resistance coating was invented to adapt to the harsh marine environment (RSC Advances, 2016).

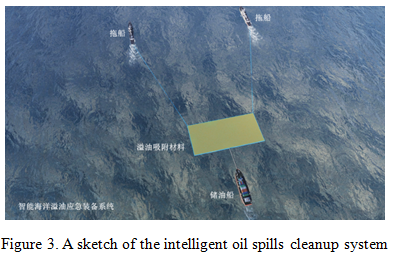

On the base of the above oleophylic and hydrophobic materials, an intelligent oil spills clean up system with area of fifty thousand square metre was developed with an enterprise in Shanghai Beidou industrial park. The intelligent oil spills clean up system consists of one unmanned aircraft, two tugboats, oil adsorption materials and one oil storage ship. The unmanned aircraftis to detect the oil spills. When oil spills occur, the system will choose and send suitable oil recycle equipment to the location according to the information sent by unmanned aircraft. There are pipelines in the oil adsorption materials which can gather the absorbed oil by the oleophylic materials to the oil storage tank. In the oil storage tank, there is a three-stage filtration system which will separate and purify the recycled oil step by step. The purified oil will send to oil storage ship. At last, the on-line monitoring device will detect the water quality of the oil spills area after clean up. If the sea water quality is not up to standard, the system will clean up again.

Dr. Zhixiang Zeng: zengzhx@nimte.ac.cn Dr Gang Wang: wanggang@nimte.ac.cn

All Images by ![]()