With the rapid development of communication technology along with electronic devices, the electromagnetic interference (EMI) problem has been increasing at a noticeable rate. Therefore, designing new high-performance EMI shielding materials is becoming an urgent challenge to be addressed. Graphene, a new class of two-dimensional carbon nanostructure, possesses not only a stable structure but also a high specific surface area and excellent electronic property, which make it very promising as excellent EMI shielding materials. The research group led by Prof. Wenge Zheng in Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences (NIMTE, CAS), has devoted great effort to the fabrication of graphene-based materials for EMI shielding over the past few years.

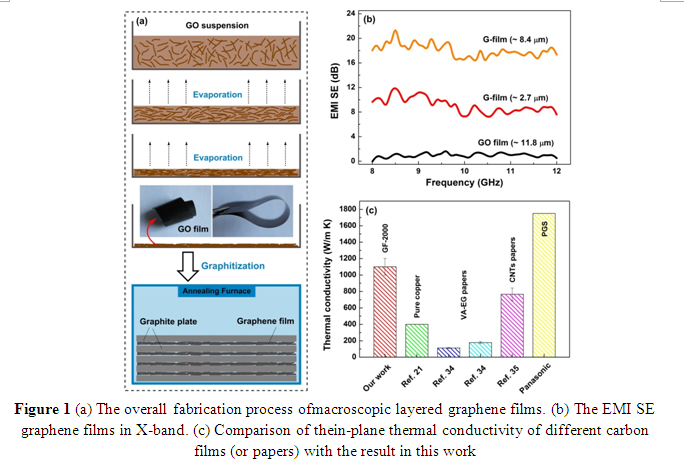

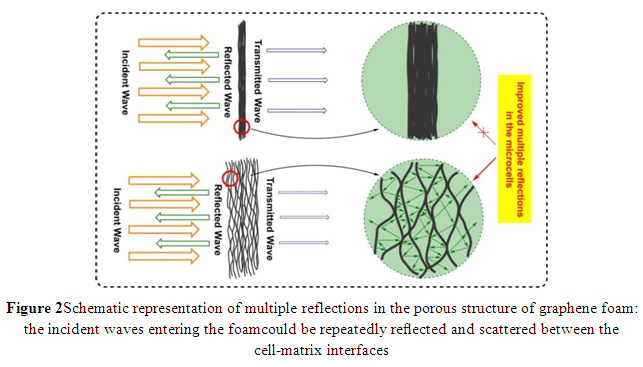

Early studies focused on dispersing graphene in to the insulating polymer matrices to form effective conductive network in composites, thereby improving the EMI shielding performance. In order to take full advantage of graphene’s superior electrical property, macroscopic layered graphene films with an electrical conductivity of ~1000 S/cm were fabricated through thermal annealing of graphene oxide (GO) films at graphitization temperature by them (Figure 1), and high EMI shielding effectiveness (SE) of ~20 dB has been achieved with effective sample thickness of only ~8 μm (Advanced Functional Materials,2014). Moreover, such graphene films were also characterized by excellent flexibility and displayed an outstanding thermal conductivity of ~1,100 W/m·K at room temperature. In addition, the more recent research work by them has further indicated that the foaming of layered graphene films into porous graphene foams could lead to an improvement in EMI shielding (Figure 2), possible due to the formation of improved internal multiple reflections owing to the existence of porous structure (Carbon, 2016).

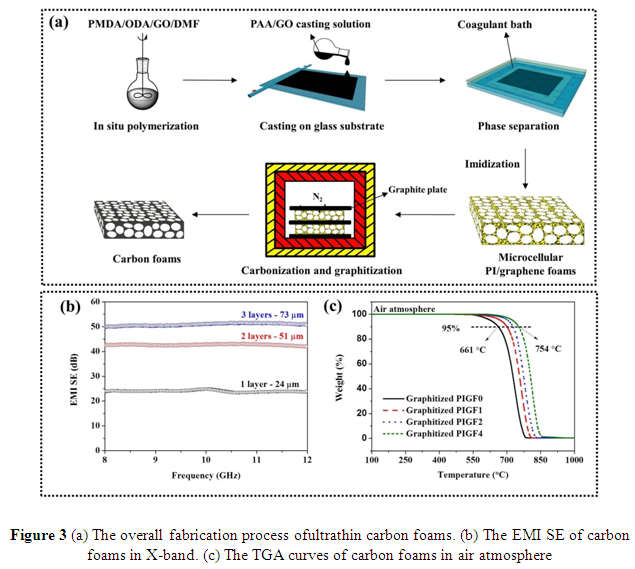

Similarly, ultrathin carbon foams with remarkable EMI shielding were fabricated by the pyrolysis (carbonization and graphitization) of polyimide/graphene composite foams (Figure 3), which were prepared by the combination of in-situ polymerization and phase separation according to the previous work (RSC Advances, 2015). The addition of graphene could stabilize the porous structure of the foams and accelerate their graphitization process simultaneously. The EMI SE was found to be substantially improved with improving sample thickness, reaching ~24 dB for the sample with thickness of only ~24 μm, and even higher value of ~51 dB for the sample with thickness of ~73 μm. Moreover, such ultrathin carbon foams had also very high thermal stability, with the decomposition temperature up to 550 °C in air atmosphere (Carbon, 2016).

Furthermore, ultralightweight and compressible graphene-based composite foams were developed by simple solution dip-coating of graphene on commercial polyurethane sponges with highly porous network structure. The resultant graphene-based composite foams had a density as low as ~0.027-0.030 g/cm3, and possessed good comprehensive EMI shielding performance together with an absorption-dominant mechanism, possibly due to both conductive dissipation and multiple reflections and scattering of EM waves by the inside 3D conducive graphene network. Moreover, taking advantage of their remarkable compressibility, the shielding performance of the composite foams could be simply adjusted through a simple mechanical compression, showing promise for adjustable EMI shielding (ACS Applied Materials & Interfaces, 2016).

The work is financially supported by China Postdoctoral Science Foundation (2015M570531), and National Natural Science Foundation of China (51473181, 61274110).

Prof. Wenge Zheng: wgzheng@nimte.ac.cn

Dr. Bin Shen: shenbin@nimte.ac.cn

All Images by ![]()