Poly(lactic acid) (PLA), one of the most promising bio-based polymeric materials, has excellent mechanical properties such as high tensile modulus and strength, and biodegradability that is crucial for a green and sustainable future for our next generation. PLA has huge potential applications in the fields that disposability is highly demanded such as food package, tableware, and package cushioning for electronic devices. As a result, it can not only diminish the use of petroleum-based polymeric materials, but also can partially solve the “white pollution” problem caused by its non-biodegradable counterparts. However, PLA is brittle with low impact strength, which largely limits its potential applications. Therefore, modification on PLA in order to improve its impact strength is strongly acquired.

The most effective and convenient method to achieve high impact strength is by blending PLA with toughening agents. People have previously developed a significantly number of toughening agents which generally fall into four categories listed below: plasticizers, inorganic/organic particles, thermoplastic elastomers, and biodegradable plastics. Plasticizers are usually small organic molecules which suffer from serious migration problems, while inorganic/organic particles have poor compatibility with the PLA matrix which requires additional interfacial modification. On the other hand, although both thermoplastic elastomers and biodegradable plastics toughening agents are able to result in PLA with improved toughness, the use of thermoplastic elastomers will compromise the biodegradability of PLA, while the use of biodegradable plastics will largely reduce the tensile modulus and strength of PLA. Therefore, none of current toughening agents are able to solve the problem in such a way that PLA does not sacrifice too much of its biodegradability and mechanical properties while its impact strength is largely enhanced.

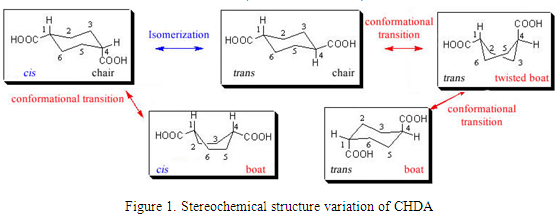

The bio-based polymeric materials research group led by Professor Jin Zhu and Associate Professor Haining Na in Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences (NIMTE, CAS) has devoted great effort to the toughening of PLA over the past few years. Recently, by combining the advantages of both thermoplastic elastomers and biodegradable plastics, they introduced a new member to the family of PLA toughening agents. The new toughening agent, biodegradable thermoplastic elastomer, is designed and developed based on a common yet unique non-planar ring structure (e.g. 1,4-cyclohexandicarboxylic acid, CHDA) (Figure 1). This structure has not only similar rigidity to its planar aromatic counterpart, but also flexibility and biodegradability resembling aliphatic chain. What’s more important, the six-membered ring structure has abundant stereochemical structure variation, including cis/trans isomerization and boat/chair conformational transition (Figure 1). Therefore, using CHDA for the synthesis of novel polymeric materials enables people to adjust the properties of the polymers in a wide range so that their properties can meet the requirement better.

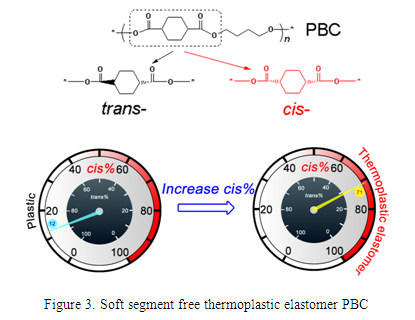

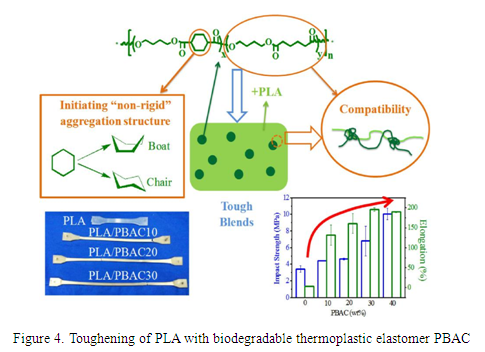

Firstly, they evaluated the potential of using CHDA for the development of thermoplastic elastomer by incorporation of the non-planar ring structure to PBT-PTMG, a traditional poly(ether-ester) thermoplastic elastomer with polyether soft segment. The tensile and thermal properties of the resulted PBCT-PTMG can be easily tuned by changing the amount of CHDA as well as its cis/trans ratio (Figure 2) (RSC Advances, 2015).Secondly, in order to eliminate all the non-biodegradable contents such as the aromatic ring structure and the polyether soft segment, PBC, a soft segment free biodegradable thermoplastic elastomer with high performance, has been successfully developed by simple manipulation of stereochemistry of CHDA without using polyether soft segment. PBC turns from a plastic to an elastomer when the cis-CHDA amount is 71% (Figure 3) (Journal of Materials Chemistry A, 2015, 3, 13637,Chinese Patent Application No. 201410609985.8). Finally, based on the above results, PBAC, a thermoplastic copolyester elastomer synthesized from CHDA and adipic acid, was subsequently developed. The use of a third monomer with aliphatic chain is to gain better compatibility with the PLA matrix. PBAC was then blended with PLA to give modified PLA with PBAC amount in the range of 10 to 40%. Results shown that the blends have largely improved toughness while their mechanical properties drop only to a limited extent (Figure 4) (Composites Science and Technology, 2016).

The new toughening agent shows promising effect for the toughening of PLA and further investigations on the toughening mechanism as well as the biodegradability of the resulted blends are in progress in Prof. Zhu’s group. The work is financially supported by Ningbo Natural Science Foundation (2014A610135) and the National Natural Science Foundation of China (NSFC, 51503217).

Prof Jin Zhu: jzhu@nimte.ac.cn Associate Prof Haining Na: nahaining@nimte.ac.cn

Dr.Fei Liu: liufei@nimte.ac.cn

Research Gruop Url : http://english.nimte.cas.cn/rh/rd/bp

All Images by ![]()