Hot deformation process is of foremost method to prepare nanocrystalline anisotropic Nd2Fe14B magnets. Grain boundary phases in hot-deformed Nd2Fe14B magnets are considered to be of crucial importance for texture formation in hot deformation process. Due to the lack of grain boundary phases in rare earth (RE) lean Nd2Fe14B magnets, excellent crystallographic and magnetic textures are difficult to be obtained. Besides, the existence of eutectic low melting phases in grain boundaries plays a critical factor for coercivity enhancement in Nd2Fe14B magnets.

In order to investigate the mechanism of texture formation in RE-lean nanocomposite Nd2Fe14B magnets, Prof. Chen and his group in Ningbo Institute of Materials Technology and Engineering (NIMTE, CAS) have introduced Nd-Cu eutectic alloy into grain boundary by controllable grain boundary diffusion. The nanocomposite Nd2Fe14B magnets with excellent texture degree and optimized grain boundary are successfully obtained. The remanence and coercivity of the Nd2Fe14B-Fe bulk magnets are largely increased as shown in Fig. 1. The results indicate that the existence of low melting point alloys in grain boundaries is beneficial for grain texture optimization and coercivity enhancement. The investigation on mechanism of texture formation indicates that the eutectic Nd-Cu alloys flow along surface of the particles and then the eutectic Nd-Cu alloys diffuse into grain boundaries. The existence of grain boundary phases largely enhances the texture formation of nanocrystalline grains. Meanwhile, due to the magnetic isolation by nonmagnetic phases between grains, the coercivity is dramatically increased by the decoupling interaction.

The above results have been published on Applied Physics Letters(2013), Scripta Materialia(2014) and Journal of Alloys and Compounds(2015).

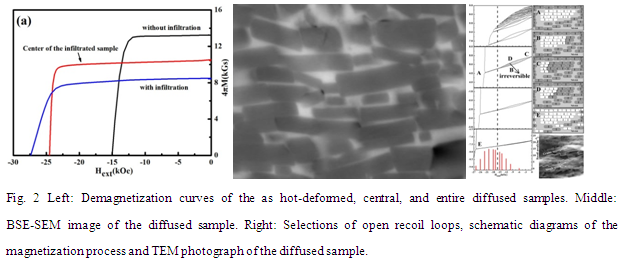

The previous investigations have demonstrated that the grain boundary structure adjustment is obviously effective for the optimization of texture formation ability and coercivity enhancement. The result reminds us that the grain boundary modification is also an effective way to develop ultrahigh coercivity Nd2Fe14B magnets without heavy RE substitution for Nd. Recently, Prof. Chen and his group have successfully developed ultrahigh coercivity hot deformed Nd2Fe14B magnets up to 27 kOe by low melting point PrNd-Cu grain boundary diffusion process. The platelet shaped Nd2Fe14Bsingle grains and RE-rich grain boundary phases are both observed as illustrated by grey and white contrasts, respectively. Due to the magnetic isolation by nonmagnetic grain boundary phases, the decoupling interaction is largely strengthened that results in the large coercivity enhancement. Besides, open recoil loops are also obtained as shown in Fig. 2. The phenomenon is considered to be caused by the inhomogeneous diffusion in the hot-deformed magnets. The schematic diagrams of the magnetization process are also given to investigate the appearance of open recoil loops.

The above results have been published on Applied Physics Letters(2015).

Prof. Renjie Chen: chenrj@nimte.ac.cn, Prof. Aru Yan: aruyan@nimte.ac.cn

Dr. Xu Tang: tangxu@nimte.ac.cn

All Images by ![]()