The discharge of waste oils or oily waste water without treatment has caused serious threat to water resources. How to separate the oil from the oily waste water has significantly meanings to human health and the environment. The phase separated oil/water contaminant is relatively easy to treat due to the incompatibility and density difference between oil and water. But the oil–water emulsion is difficult to treat due to its micro dimensions and good stability, especially when stabilized by surfactants. Currently, superhydrophilic and superoleophobic materials attract much attention in oil/water separation due to its environmental friendliness, low energy consumption and simplicity. Nevertheless, the surface energies of oils and organic solvents are much lower than that of water which means that superoleophobic surfaces are always superhydrophobic. Additionally, conventional superoleophobic surfaces consist of low energy materials or possess a ‘re-entrant surface texture’ structure in general which is costly or difficult for scalable fabrication. Furthermore, many in-air superoleophobic surfaces typically lose their oleophobicity under water. So, a simple, efficient and environmental friendly material is urgently needed for the purification of oily waste water.

Dr. Zhixiang Zeng and co-workers from Ningbo Institute of Material Technology and Engineering (CNITECH),fabricate a cellulose sponge with stable wettability of superoleophobicity (θoil>150o) under water and superhydrophilicity (θwater≈0o) under oil without any further chemical modification for oil/water emulsion separation. The cellulose sponge shows superoleophobicity to various oils under water and possesses stable super oleophobicity in corrosive liquids like strong acid, alkali and salt solution. The sponge is made from the dissolution and regeneration of cellulose powder which was green, low cost, simple and easy to scale up. The native hydrophilic of the cellulose ensures its excellent underwater superoleophobicity and antifouling. The double layer construction of different pore sizes, which contents of a top-layer with a pore size of lower than 1μm and a sub-layer with a pore size of larger than 3μm, makes sure the oil phase resist and water phase easy and quickly permeate the sponge. Our cellulose sponge can separate oil/water mixtures, with >99.94% separation efficiency, solely using gravity and excellent antifouling properties. Related results have been published on Green Chemistry.

Figure 1. (a)~(c) Digital picture of toluene-in-water emulsion before filtration after filtration. (d) Oil contact angles of cellulose sponge under the water. (e) UV-VIS spectra for the toluene-in-water emulsion before and after filtration.

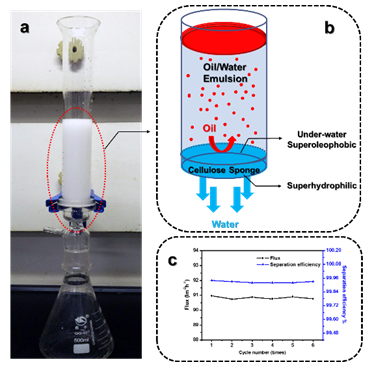

Figure 2.(a) The filtration system used in the oil/water separation process. (b) Illustration of the oil/water separation process. (c) Cycling performance of the sponge for oil/water separation.

Dr. Zhixiang Zeng: zengzhx@nimte.ac.cn

All Images by ![]()