Gas compression refrigeration technology is now widely used in various fields, but it has two problems, one is its low efficiency, which has utilized only 30% Carnot cycle’s effiency; the other is environmentally unfriendly due to its chemical refrigerant, which destroys ozone layer and makes greenhouse effect. Today, energy and environment are the two key issues in modern society; therefore traditional gas compression refrigeration technology needs great innovation. The method to solve these problems is to look for new refrigeration technique with high efficiency, no pollution as well. Comparing with traditional refrigeration technology, newly developed magnetic refrigeration is environmentally friendly, high energy efficient, low noise, easy maintenance. For those reasons, magnetic refrigeration is considered to have a potentially wide application in refrigerator, air conditioner, supermarket food refrigeration systems, et al.

As the key part of magnetic refrigeration technology, the choice of magnetic refrigerants with large magnetocaloric effect (MCE) is of crucial importance to gain good refrigeration effect. The most important parameter of MCE materials is high adiabatic temperature change, and its substitution counterpart is high magnetic entropy change, which is easy to be measured and therefore became the property which most investigators are concerned. But from the view point of application, suitable curie temperature, high magnetic entropy change, high refrigeration capacity, good mechanical property, small hysteresis and thermal hysteresis are the key factors which need to be considered before its real application.

One method to optimize MEC is doping with different elements or interstitial small atoms. The effect of tuning curie temperature by doping small atom H which can occupy interstitial sites was first discovered in La-Fe-Si system. After that, many researchers found that small atoms, such as C and B, also have similar effect on tuning curie temperatures in La-Fe-Si systems. However, the disadvantage of doping small interstitial atom or other elements will decrease the magnetic entropy change at different degree depends on variety of atoms and concentrations. The other method to enhance magnetic refrigeration properties is to optimize the preparation process. There are two methods to prepare MCE materials, arc-melting and rapid solidification (melt spinning) followed by annealing. It is found that these two methods have different effects on MCE including hysteresis. Additionally, due to the first order magnetic transition accompanied with most of the magnetic refrigeration materials with large magnetic entropy change, magnetic hysteresis and thermal hysteresis are also important factors to affect real application. Only after the mechanism of hysteresis and influencing factors are systematically studied and understood, is it possible to reduce hysteresis (including magnetic and thermal hysteresis) effectively.

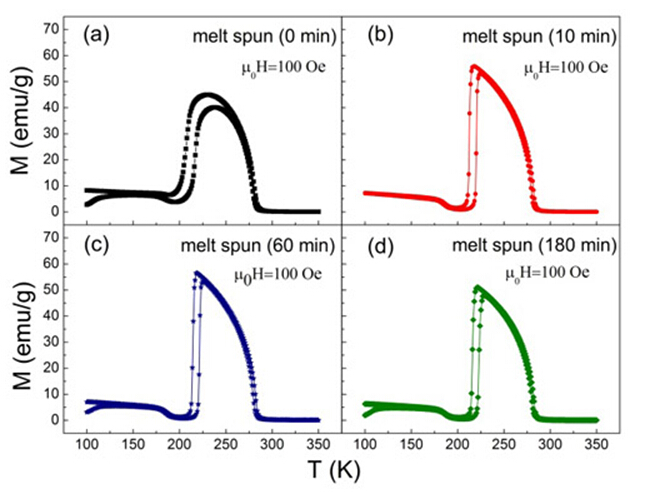

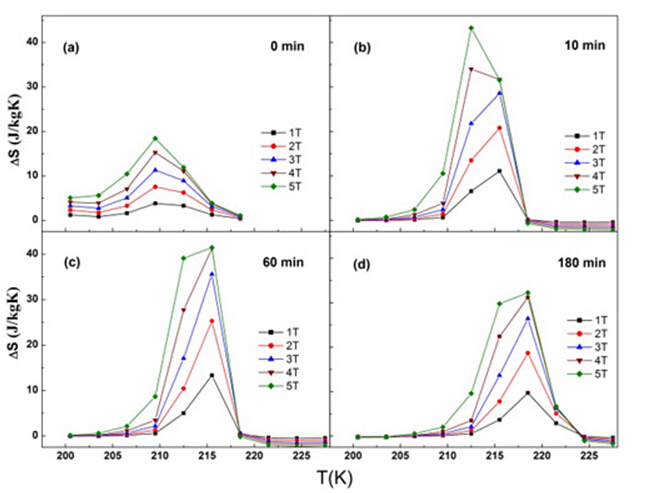

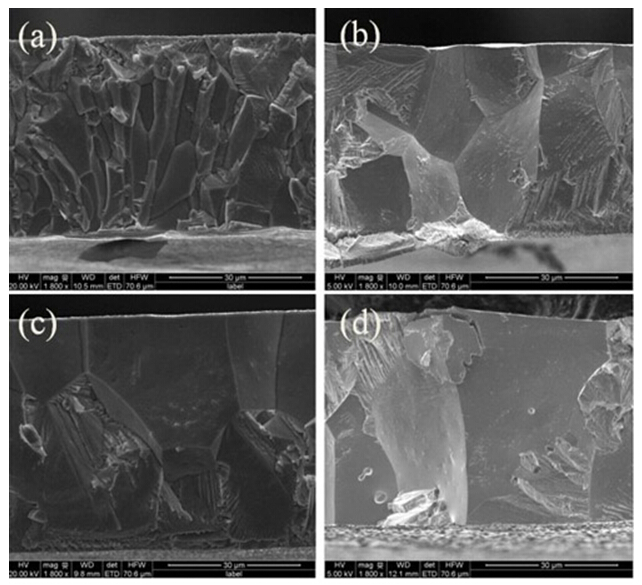

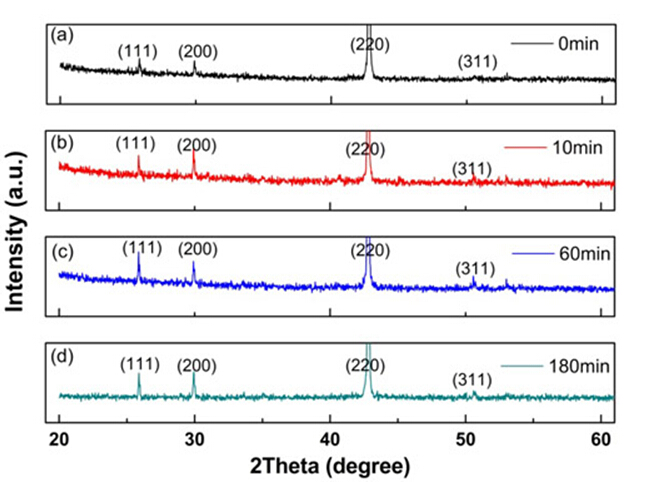

Magnetic refrigeration properties of Ni-Mn-Sn Hesuler alloys were systematically studied in laboratory of rare earth magnetic functional materials, Ningbo Institute of Material Technology and Engineering (NIMTE), Chinese Academy of Sciences (CAS); and School of Materials Science and Engineering, Ningbo University of Technology. Interstitial C atoms were successfully introduced into Ni-Mn-Sn alloy, and in this way, not only curie temperature was increased by 50 K, but also magnetic entropy change was improved by 26 % from 27.4 J(kgK)-1 for Ni-Mn-Sn alloys without C to 34.6 J(kgK)-1 with C-doped Ni-Mn-Sn alloys. Aimed to solve the brittleness and difficult machinability, in our previous research, the content of C was increased, and thus the inner carbide was formed as precipitated strengthened second phase. Therefore, the mechanical property, such as fracture strength, was dramatically improved (by 82.7%) from 556 MPa for Ni-Mn-Sn alloys to 1016 MPa for C-doped Ni-Mn-Sn alloys [Scripta Mater. 75,26(2014)]. Both arc melting and rapid solidification were used to prepare NiMnSn alloys and it was found that the later method can substantially enhance magnetic entropy change by 40%, that is 41.4J(kgK)-1 comparing with 29.5J(kgK)-1by the former method. And at the same time, rapid solidification method can also increase magnetic refrigeration capacity and reduce both magnetic and thermal hysteresis substantitially [Scripta. Mater.04.004(2015)]. Our more recent work was aimed to the optimization of post-annealing process for Ni-Mn-Sn ribbons obtained by rapid solidification. A maximum magnetic entropy change of 43.2 J(kgK)-1 was found and refrigeration capacity of 115.4 J kg-1 was obtained as well. The more important significance of this work is to give a guide for how to improve magnetic entropy change and simultaneously decrease the hysteresis in Ni-Mn-Sn alloys with martensitic transformation after systematically investigations and deep discussions based on the effect of microstructure, microcomposition, atomic order degree, on martensitic transition, magnetic property and magnetic refrigeration properties. [Sci. rep. 5,11010 (2015)].

Prof. Juan Du: dujuan@nimte.ac.cn

Research Staff Url:

http://english.nimte.cas.cn/rh/rd/nmm/nmm_research_interests/

All Images by ![]()