Recently, flexible electronics have attracted wide attention due to the advantages of inflexibility, wearable, and low fabrication cost etc., Flexible electronics have potential applications in areas such as health care, information technology, energy, and national security. An ideal flexible electronic device (such as wearable equipment) requires its components, i.e., power source, circuit, display, sensors and memories, etc., to be flexible. Therefore, it is very important to make traditional functional materials flexible, and study their functionalities evolving with the application of external stress/strain. On the other hand, magnetic materials are important components in electronic devices. The preparation of magnetic thin films and the investigation of their magnetic and electronic properties are very helpful for developments of flexible magneto electronic devices. The magneto electronic materials and devices group in CAS Key Laboratory of Magnetic Materials and Devices focuses on the fabrication of flexible magneto electeonic material sand devices, and the evolution of their physical properties under multi-fields. Up to now, a series of progresses have been made regarding the modulation of magnetic anisotropy by stress/strain in flexible magnetic thin films.

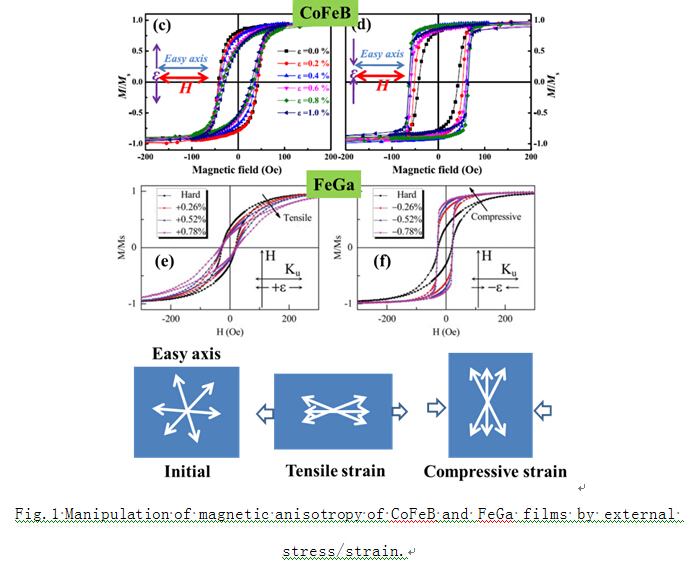

As one of the important inherent properties of magnetic materials, magnetic anisotropy not only determines the moment orientation and coercivity but also affects the operation frequency and even power consumption of a magnetic device. The development of methods to tune the magnetic anisotropy is one of the key issues in magnetic materials and physics. By depositing magneto strictive metals (such as FeGa, CoFeB, etc.) on flexible substrate, they found effective tuning of the magnetic anisotropy by applying stress/strain. For magnetic films with positive magneto striction, the magnetic easy axis tends to align along the tensile strain direction, and the hard axis tends to align along the compressive strain direction. Under certain stress state, the magnetic easy and hard axis could exchange direction. (Fig.1)[Appl. Phys. Lett. 100, 122407 (2012); Appl. Phys. Lett.105, 103504 (2014)].In flexible FaGa/IrMn exchange biased bilayers, it was found that the bias field decreases with increasing the stress field, while the coercivity increases with the increase of stress field [Appl. Phys. Lett.102, 022412 (2013)]. These results suggest that the AFM layer response differently from the FM layer to external strain, hence the pinning effect of the AFM layer weakens and the bias field decreases.

The magnetic anisotropy usually decreases with elevating temperatures, which is one of the main reasons that cause thermal instability in magnetic devices. In order to solve this problem, they utilized the anisotropic thermal expansion of PVDF, combined with the magneto elastic anisotropy of magnetic materials to design a class of magnetic composites with positive temperature coefficient of magnetic anisotropy. Three different kinds of PVDF-based magnetic composites (CoFeB/PVDF, FeGa/PVDF, and Ni/PVDF) have been examined. It was found that the magnetic anisotropy has been enhanced with increasing temperature (Fig.2) [Sci. Rep. 4, 6615 (2014)]. In the meanwhile, by utilizing the ferroelectricity and anisotropic thermal expansion of PVDF, an effective tuning of the magnetic anisotropy and magnetization orientation can be realized by external multi-fields. For example, in FeGa/PVDFhetero structure, the electric field could induce switching between the magnetic easy axis and hard axis (Fig.3), and a temperature induced 180° magnetization reversal can be realized with the aid of an external field smaller than the coercivity.

Relating works have been published in Appl. Phys. Lett. 100, 122407 (2012), Appl. Phys. Lett.102, 022412 (2013), J. Appl. Phys. 113, 17A901 (2013), J. Appl. Phys. 113, 17C705 (2013), J. Appl. Phys. 114, 173913 (2013), Chin. Phys. B. 22, 127502 (2013) (invited review), Appl. Phys. Lett.105, 103504 (2014), Sci. Rep. 4, 6615 (2014), and Sci. Rep. 4, 6925 (2014).

Prof. Runwei Li: runweili@nimte.ac.cn Prof. Baomin Wang: wangbaomin@nimte.ac.cn

Research Group Url: http://english.nimte.cas.cn/rh/rd/newmaterials/mmd/mmd_research_interests/

All Images by ![]()