Graphene, a one-atom thick honeycomb lattice derived from graphite, is as versatile a material as any discovered on Earth. With its unique structure and extraordinary electronic, thermal, and mechanical properties, graphene has been integrated into a huge number of applications including optical electronics, photovoltaic cells, energy storage, composite materials, ultrafiltration, biological engineering, and intelligent coatings for EMI shielding, anti-static or anticorrosive protections. However, like other nanoscale materials, graphene nanoplatelets have a tendency to aggregate due to its hydrophobic feature and strong - interaction. A prerequisite for exploiting most proposed applications is the availability of processable or dispersible graphenes in large quantities in order to exhibit their optimal properties.

In general, the chemical modification of graphene or addition of dispersing agents is necessary to render graphene to form stable dispersions in organic solvents or even in water. However, the chemical modification approach is prone to induction of defects in graphene which alters its electrical, chemical, mechanical properties. On the other hand, the current developed polymeric or surfactant additives showed limited capacity for graphene dispersions.

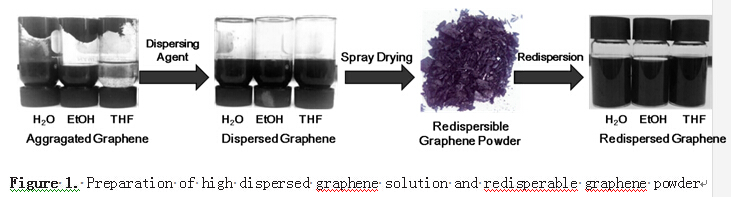

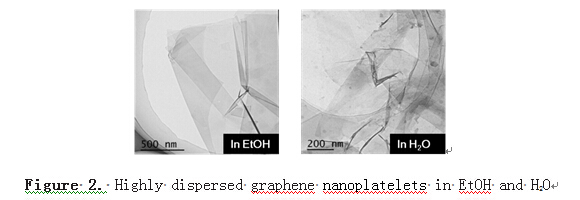

To address this issue, Prof.Yu Haibin's group has designed and synthesized a series of highly efficient graphene dispersing agents. These novel graphene dispersing agents combine ease of synthesis, less synthetic step, low cost and without using any organic solvents during the synthesis, enabling to develop a facile approach to large-scale production of aqueous or organic graphene dispersions, as well as redispersible graphene powders (Figure 1). The typical TEM image revealed that graphene nanoplatelets are highly dispersed in aqueous solution or in many organic solvent with a high concentration of 5 mg/mL (Figure 2).

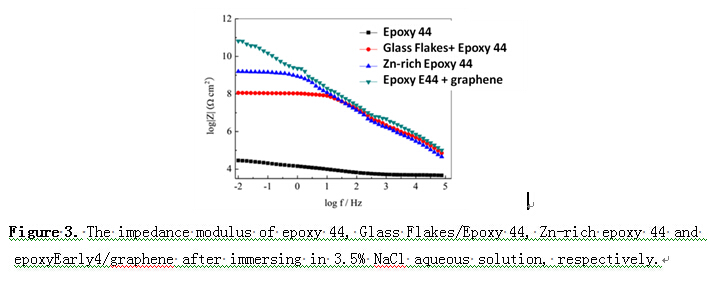

This highly efficient graphene dispersion technique opens up enormous opportunities to process graphene materials for many technological applications, including conductive inks, transparent conducting films, batteries, supercapacitors, thermal conductive composites, anticorrosion and antistatic coatings. Research progress in this laboratory has revealed that the incorporation of 0.5 wt% highly dispersed graphene into the epoxy-based coatings could remarkably improved its anticorrosive performance (Figure 3).

To present, 14 graphene-related patents including graphene dispersion technique and its subsequent applications have been issued in this laboratory.

Hongyan Zhou: zhouhongyan@nimte.ac.cn

All Images by![]()