The research on exploring renewable and green feedstock tore place fossil resource has been promoted strongly due to the fossil resource depletion and the awareness of environment crisis. Glucose as a promising green feedstock was emphasized by researches during past decades because of its feasibility to convert to food, chemical sand fuel by the simple biological and/or chemical processes. Therefore, hydrolysis of cellulose (which is the most abundant and sustainable biomass resource on the earth) to produce the nonfood-competing glucose, is recognized as one of the most important research directions.

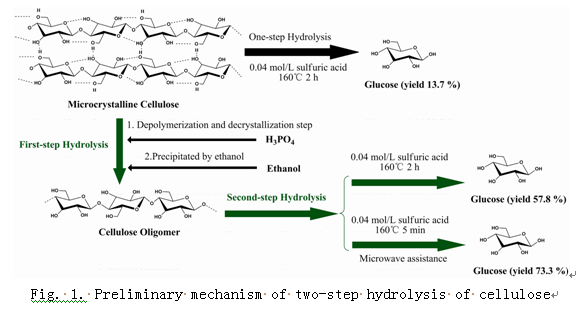

The research group led by Professor Jin Zhu and Associate Professor Haining Na has developed a two-step acid-catalyzed hydrolysis methodology to effectively hydrolyze cellulose to glucose with high yield and selectivity under mild conditions. In multi-steps hydrolysis, the difficulty of cellulose can be effectively reduced under mild conditions. In the first step, microcrystalline cellulose was depolymerized in phosphoric acid to cellulose oligomer at 50°C. Then the oligomer was precipitated by ethanol and hydrolyzed with dilute sulfuric acid in the second step. 87.7% total reducing sugars and 57.8% glucose was released from the two-step hydrolysis. In addition, with the assistance of microwave in the second step, the yield and selectivity of glucose can be improved to 73.3% and 80.1%by only 5min hydrolysis (Fig.1).

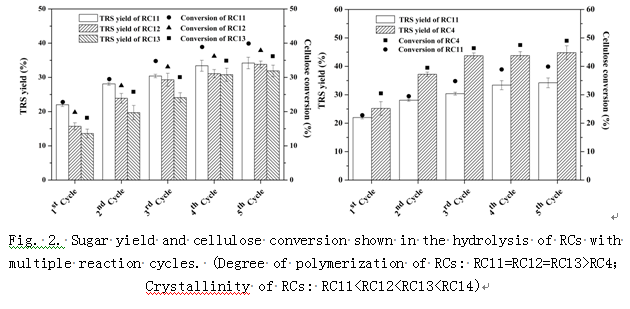

In addition, the responsive behavior of regenerated cellulose (RC) in hydrolysis under microwave radiation was studied. Four types of RC with different crystallinity (Cr) and degree of polymerization (DP) are produced to evaluate the reactivity of RC by step-by-step hydrolysis. Results show Cr is the key factor to affect the reactivity of RCs. With hydrolysis of amorphous region and the formation of recrystallization, the Cr of RC reaches a high value and thus weakens the reactivity. As a result, the increment of cellulose conversion and sugar yield gradually reduces. Decrease of the DP of RC is helpful to increase the speed at the onset of hydrolysis and produce high sugar yield. But, there is no direct influence with the reactivity of RC to prolong the time of pretreatment(Fig.2). This research provides an accurate understanding to guide the RC preparation for sugar formation with relative high efficiency under mild reaction conditions.

The results have been published on Bioresource Technology(2013, 137, 106-110&2014, 167, 69-73) and two related Chinese patents have been filed(201210163175.5, 201310300731.3)

Jinping Ni:nijp@nimte.ac.cn

All Images by![]()