Aluminum and aluminum alloys possess excellent physical and mechanical properties, such as high electrical capacity, low density and high energy density. Thus, they are important materials due to their wide range of industrial applications, especially in the aerospace and household fields. However, aluminum alloys are active and prone to corrosion in water or other corrosion environments, which limits their wider application. Thus, it is important to improve the corrosion resistance properties of aluminum alloys.

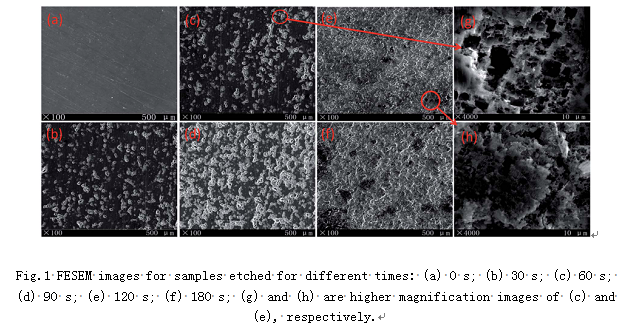

Recently, Prof. Xuedong Wu’s group at the Ningbo Institute of Materials Technology Engineering (CNITECH) using a simple and versatile procedure combines micro/nano-hierarchical structures and further modification with low surface energy molecules to fabricate hydrophobic and hydrophilic films on aluminum alloy AA 2024 substrates. The procedure is very impressive for its universality, simplicity and flexibility, which can be applied to treat a wide range of aluminum alloys. Moreover, the chemical etching (CE) agent is HCl, which is cheap and easy to obtain.

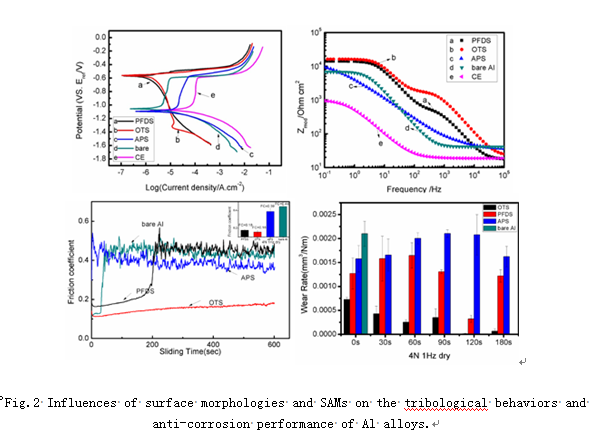

The as-prepared octadecyltriethoxysilane (OTS) SAMs and 1H,1H,2H,2H-perfluorodecyltriethoxysilane (PFDS) SAMs showed better anti-corrosion capability compared with the 3-aminopropyltriethoxysilane (APS) SAMs and bare samples because of their surface hydrophobicity. The OTS SAMs exhibited excellent tribological behavior as compared with PFDS-SAMs, APS-SAMs and bare samples due to their long alkyl chains. The CE time is the critical factor for the surface morphology fabrication. And it is important for the anti-corrosion and tribological performance.

This work provides a new and effective protection method for Al alloys, which can prevent future corrosion via simple chemical modification with SAMs, removing the need for replacement of the whole Al alloy. Through a combination of micro/nano-structure and chemical composition design, Al alloys with excellent anti-corrosion and tribological performance were obtained.

Key Words: chemical etching; SAMs; anti-corrosi¬o¬n; tribologic¬a¬l properties; aluminum alloys.

Prof.Xuedong Wu: xdwu@nimte.ac.cn

Research Staff Url: http://english.nimte.cas.cn/pe/fas/200909/t20090929_44484.html

More details of this work can be found in RSC Adv., 2014, 4, 60307-60315.

All Images by ![]()