Bulk metallic glasses (BMGs), which exhibit favourable mechanical properties, have attracted significant attention as novel structural materials because they possess many advantages in terms of engineering applications, such as outstanding high yield and fracture strength, large elastic strain, high stored energy up to final failure, excellent corrosion resistance and good wear resistance.

However, most monolithic BMGs usually exhibit catastrophic failure during room temperature deformation due to highly localized shear bands, which limits the possible applications of BMGs. Therefore, to obtain monolithic BMGs with high plasticity and understand the reason why some metallic glasses are brittle whereas others are relatively ductile are of great importance from both scientific and engineering perspectives.

Recently, Run-Wei Li’s group at the Ningbo Institute of Materials Technology & Engineering, the Chinese Academy of Sciences (CAS), has found that the dramatic composition effect on ductile/ brittle behaviour of metallic glasses in different thermal history states can be well understood by the new concept of classification of BMGs.

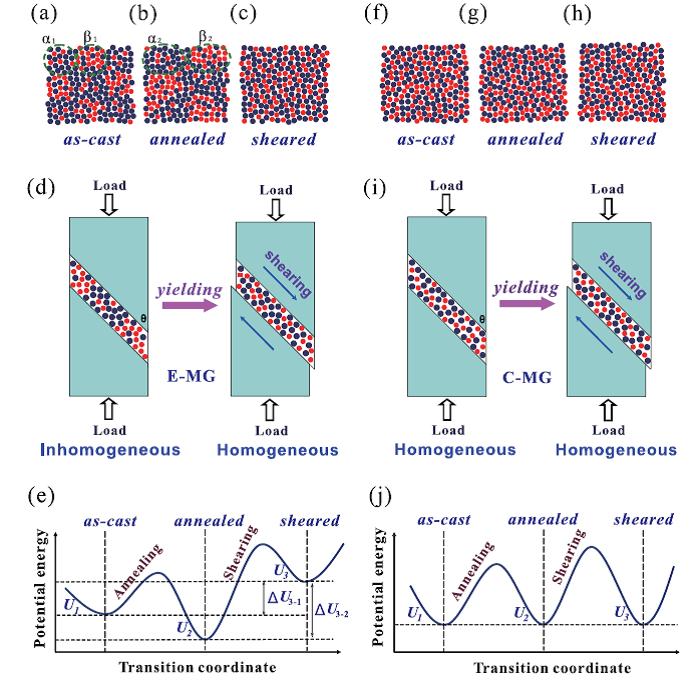

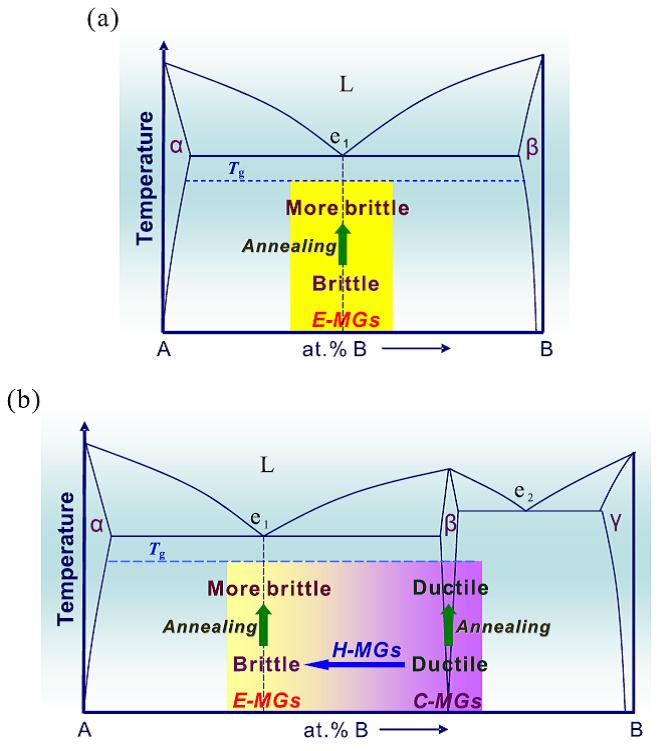

They systematically clarified that metallic glasses located at or near eutectic compositions (E-MGs) in the as-cast state were brittle, whereas those located at or near intermetallic compound compositions (C-MGs) were ductile. Although the progress of structural relaxation by annealing caused an increase in yield strength, hardness and density for both the E-MGs and the C-MGs, its influence on plasticity was dependent on the types of metallic glass. Specifically, the limited plasticity of the E-MG alloys corresponding to a number of bulk glassy alloys decreased further with annealing, whereas the high plasticity of the C-MG alloys was preserved.

This finding is supposed to enhance the application potential of the BMGs as structural materials, even in the case where thermal treatment is unavoidable. Moreover, the researchers also proposed a new interpretation that the physical and chemical origins for the appearances of ductile C-MGs and brittle E-MGs with various thermal history states were closely related to the element distribution features of metallic glasses, being inconsistent with the previous empirical rules or common concepts, which correlated the ductile/brittle behaviour of metallic glasses with Poisson’s ratio or free volume change, etc.

Based on this view of point, they have revealed a close correlation between element distribution characteristics and plasticity of metallic glasses, which gave implications to understand intrinsic ductile/brittle behaviour of metallic glasses with wide ranges of compositions and thermal histories (Fig.1). The present discovery also provided useful and universal guidelines, based on the information of phase diagrams (Fig. 2), to aid in searching for new ductile BMGs at or near the intermetallic compound compositions in other known and unknown glass-forming alloy systems.

More details of this work can be found in Scientific Reports 4 (2014) 5733.

Fig. 1 Schematic diagrams of a deformation model of metallic glasses with different composition characteristics and thermal histories

Fig. 2 Schematic diagrams illustrating the composition dependence of intrinsic plasticity or brittleness in metallic glasses with different compositions and thermal histories

Key Words: bulk metallic glasses, mechanical properties, intermetallic compounds, element distribution, phase diagrams

Prof. Runwei Li runweilil@nimte.ac.cn

Research Group Url: http://english.nimte.cas.cn/rh/rd/mmd

All Images by ![]()