The performance of aircraft engines is closely related to working temperature. Air will be compressed into combustion chamber through fan to react with fuel violently, and then high temperature and high pressure gas spew out to drive the turbine blades and generate electricity and thrust. The hot end components of the engine, especially the turbine guided vanes and blades, need to work reliably for a long time in an extreme environment with high temperature and high pressure.

In this case, effective measurement should be taken to guarantee stability of material and structure for blade , since working temperature of modern aircraft engines has exceeded the threshold temperature of high-temperature alloys.The primary technology is film cooling or thermal barrier coating (TBC) on surface of high-temperature alloys. Prof. Wenwu Zhang’s Group from the Ningbo Institute of Industrial Technology, CAS developed a single-step laser precision manufacturing process for 3D irregular holes. The research achievement has great significance in improving gas film cooling hole processing technology for aircraft engines.

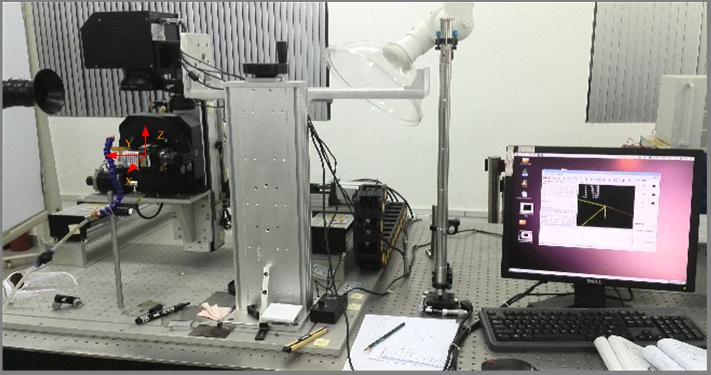

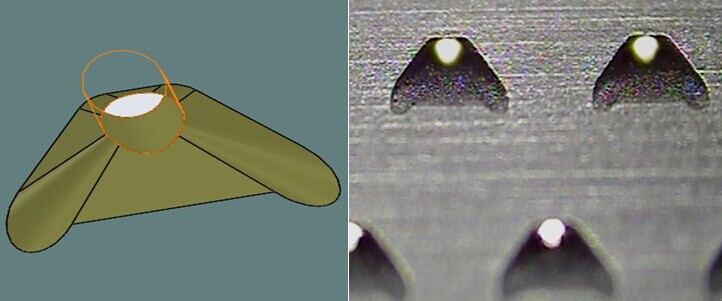

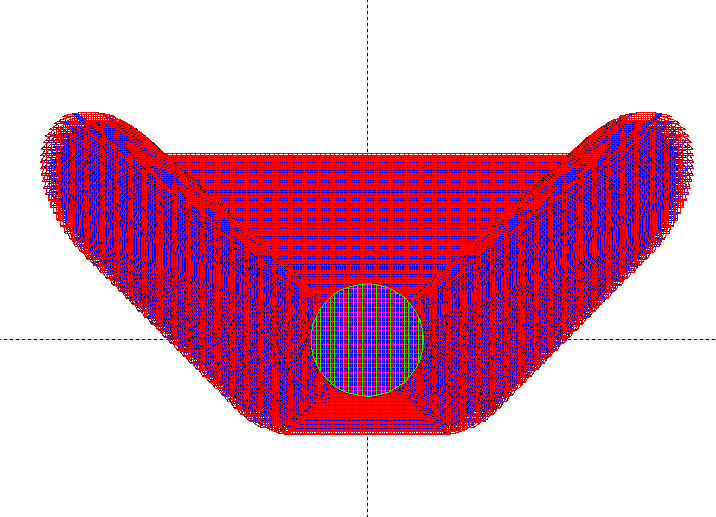

The group has been working on laser high-speed picosecond/nanosecond precision manufacturing since August 2012. As shown in Figure 1, the group independently developed a 5+2-axis short pulse laser processing system for irregular holes, which combined a 5-axis precision positioning system with a 2-axis scanning galvanometer system. 3D irregular holes have been successfully processed in single crystal high-temperature alloy, aluminum alloy, CMC, graphite, and other materials (Figure 2) by using the 5+2-axis laser processing system and independently R&D layered CAM software system for irregular holes (Figure 3). The inclination of designed irregular holes is between 30-12 degree. It is much more difficult to process irregular holes compared with conventional straight holes in new advanced composite materials. Further work has been being carried out in order to improve the processing speed and depth.

Figure 1. 5+2-axis short pulse laser processing system for irregular holes

Figure 2. 3D irregular hole (left) ; High-quality 3D irregular hole samples in single crystal high-temperature alloy, aluminum alloy, CMC, graphite, and other materials (right)

Figure 3.Initial development of CAD/CAE/CAM 3D laser precision manufacturing software system for irregular holes

The research achievement was reported in the 11th National Conference on Laser Processing.

Prof. Wenwu Zhang zhangwenwu@nimte.ac.cn

All Images by ![]()