According to the latest epidemiology statistics, there are about 1.5 million of patients suffering from toxuria, however, only 10% of them have the chance to be treated by hemodialysis. The yearly market capacity of dialyzers in China reaches up to 30 million. 90% of the global market was occupied by companies from Germany, America, and Japan. In domestic market, only Weigao and Langsheng are able to produce hollow fibers and dialyzers.

Hemodialysis membrane, known as artificial kidney, which removes blood toxins by diffusion and convection across the porous membrane and therefore restores a fluid and solute balance in the patient’s body, is the most important therapy for renal failure, especially for the end-stage renal disease (ESRD). Cellulose and its derivatives are considered as the first generation of polymers usually used in dialyzers; however, the weak hydraulic permeability and low molecular weight cutoff near 2,000 daltons have limited the prospect of cellulose-based materials.

Synthetic polymers such as Polysulfone, Polyether sulfone, Polyacrylonitrile, Polyamide and Polymethylmethacrylate have been widely used and studied, which can be regarded as the second generation of dialysis membrane. Compared to cellulose membrane, synthetic fibers are 10 times more permeable and able to be tailored to a range of molecular weight cutoffs. Nevertheless, the intrinsic hydrophobicity of synthetic polymer has adverse influence on the biocompatibility, which may lead to blood clotting.

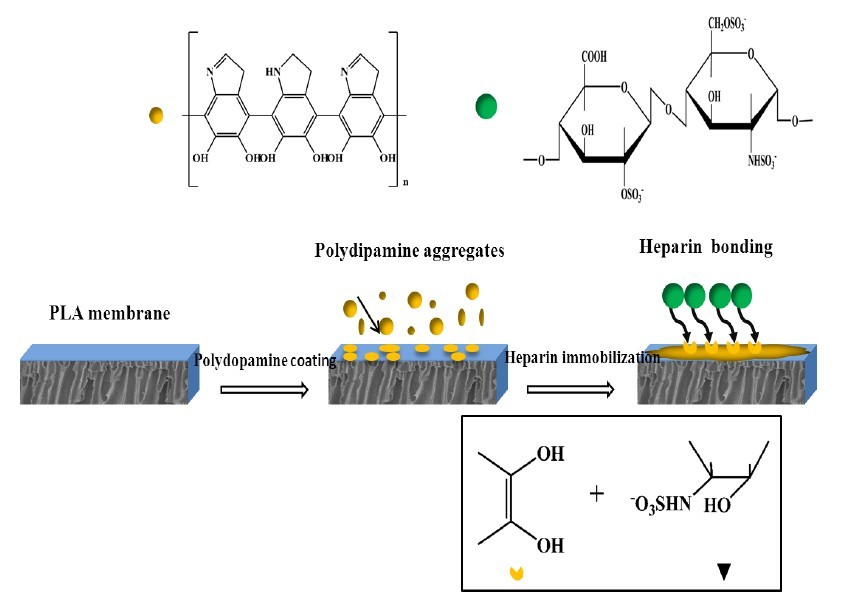

The research group led by Associate Professor Fu Liu and Professor Lixin Xue has developed a novel Poly (lactic acid) (PLA) membrane with better comprehensive properties including better dialysis performances, biocompatibility, and controlled degradation processing after use. Bio-based PLA membrane with asymmetric porous structure has been developed via phase inversion technique for the first time. Heparin was immobilized to PLA membrane surface through the strong adhesion ability of dopamine (Fig.1).

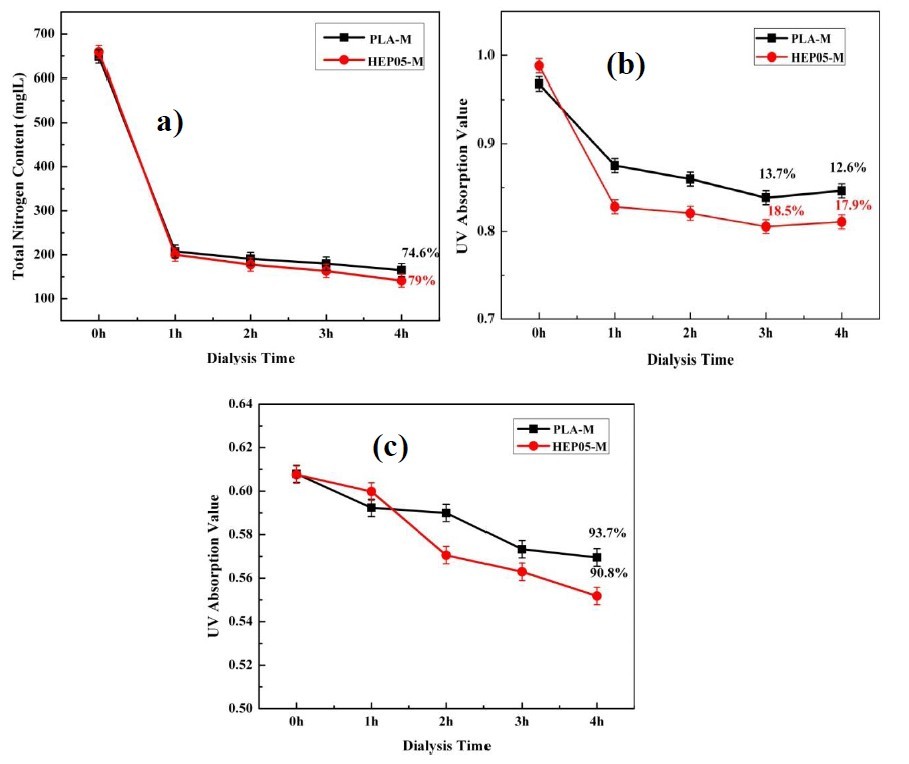

It was found that PLA membranes exhibited asymmetric finger-like pore structure. The heparin-immobilized PLA membranes showed smooth surface, better hydrophilicity and permeability. The native PLA membrane exhibits better platelet adhesion, shorter plasma recalcilication time and considerable hemolysis ratio compared to PSf membrane. Furthermore, the surface heparinization on PLA membrane improved the platelet adhesion, plasma recalcilication time and decreased hemodialysis ratio significantly. The dialysis simulation test revealed that heparin-immobilized PLA membrane cleaned almost 80% urea, 18% lysozyme and retained over 90% BSA (Fig. 2). All results demonstrated that there is a great potential application for heparin-immobilized PLA membranes in hemodialysis therapy.

The results have been published on Journal of Membrane Science (Volume 452, 15 February 2014, Pages 390–399)and three related Chinese patents have been filed.

|

|

Fig.1 Dopamine-coating and heparin-grafting onto PLA porous membranes

Fig. 2 Solute transmission efficiency of PLA-M and HEP05-M: (a) urea clearance percentage; (b) lysozyme clearance percentage; (c) BSA retention percentage

Prof.Fu Liu fu.liu@nimte.ac.cn

Research Group Url: http://english.nimte.cas.cn/rh/rd/fpm

All images by