Due to the increasing concern about the depletion of fossil reserves and greenhouse gas emission, a large quality of natural polymers and bio-based thermoplastics, such as starch, cellulose, polylactic acid (PLA) and polyhydroxyalkanoates (PHA) as well as the polyethylene derived from sugar cane have been developed as the ideal products to replace the petroleum-based polymeric materials. However, compared with the rapid progress on bio-based thermoplastics, the research on bio-based thermosetting resins, especially bio-based epoxy resins, has been overlooked. Nowadays, almost 90% of the world production of epoxy resins is diglycidyl ether of bisphenol A (DGEBA) . However, Bisphenol A from fossil resources and toxic to organism has been banned in areas directly contacting with body by many countries. Thus, synthesis of bisphenol A-free epoxy resins from bio-derived chemicals is of great significance.

Itaconic acid, or methylenesuccinic acid, is produced by fermentation of carbohydrates such as glucose using aspergillus terreus. Because of its low price and great potential to replace the petrochemicals in the chemical industry, it has been selected as one of the top 12 potential bio-based platform chemicals by U.S. Department of Energy.

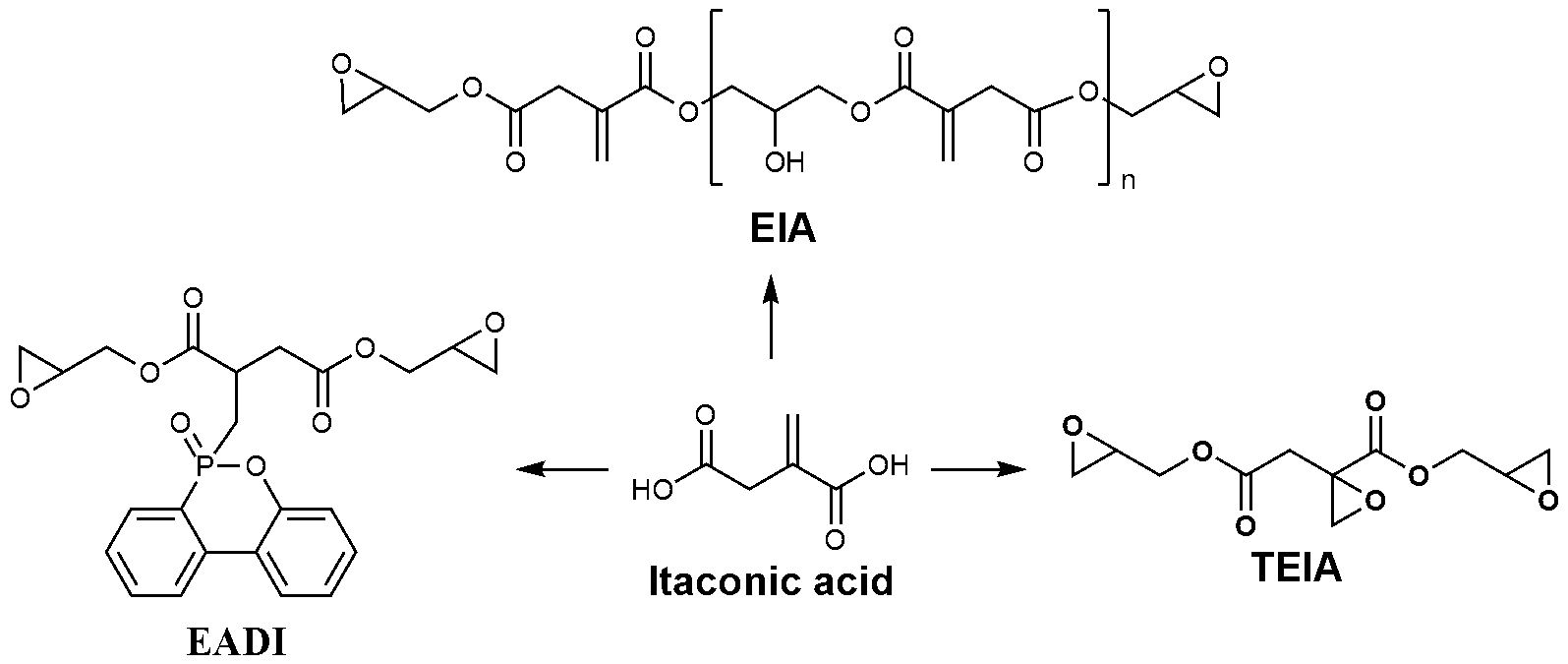

Recently, a research group on bio-based polymer led by Prof. Jin Zhu at the Ningbo Institute of Materials Technology and Engineering (NIMTE), the Chinese Academy of Sciences (CAS) synthesized a double bond containing itaconic acid based epoxy resin (EIA). This epoxy resin showed low viscosity, high epoxy value (>0.62), as well as simple synthesis process and low cost. Compared with DGEBA, this epoxy resin exhibited comparable or better properties after curing with the same curing agent, and its properties could be further regulated due to the double bond. Thus this epoxy resin has a great potential utilization. The results have been published in Green Chemistry (IF=6.82) (Green Chem., 2013, 15, 245–254, Full Paper) and meanwhile, three Chinese patents (201110245232.X, 201210196485.7, 201210196521.X) have been filed, and one of them has been authorized.

Considering the double bond of itaconic acid and the low flame retardancy of epoxy resins, Prof. Zhu’s group chemically incorporated a fire-resistant DOPO into the itaconic acid based epoxy resin and got a phosphorus-containing itaconic acid based epoxy resin (EADI). As a matrix, its cured epoxy network showed comparable glass transition temperature and mechanical properties to diglycidyl ether of bisphenol A (DGEBA) system as well as excellent flame retardancy with UL94 V-0 grade during vertical burning test. As a reactive flame retardant, it showed good flame-resistant effect on DGEBA/ MHHPA system. EADI has shown great potential to be used as a green candidate for fire-resistant applications in some fields. Up to now, two Chinese invention patents have been filed about this epoxy resin (201310035530.5, 201310034348.8).

EIA was a mixture of different oligomers,and its remaining double bond was used during the curing process. Prof. Zhu’s group planned to make the best use of the carboxyl groups and double bond of itaconic acid during the synthetic process and designed a trifunctional epoxy monomer (TEIA) which showed high epoxy value (1.16) and low viscosity (0.92 Pa s, 25 oC). Due to the high epoxy value, its properties could be manipulated and high-performance materials could be obtained by selecting different curing agents. Due to the low viscosity, TEIA systems had better processability than DGEBA systems. The results has been published in Chemsuschem (IF=7.475) (ChemSusChem, 2013, 10.1002/cssc.201300749, Full Paper) and a Chinese invention patent has been fllied (201310042243.7).

Itaconic acid, or methylenesuccinic acid, is produced by fermentation of carbohydrates such as glucose using aspergillus terreus. Because of its low price and great potential to replace the petrochemicals in the chemical industry, it has been selected as one of the top 12 potential bio-based platform chemicals by U.S. Department of Energy.

Recently, a research group on bio-based polymer led by Prof. Jin Zhu at the Ningbo Institute of Materials Technology and Engineering (NIMTE), the Chinese Academy of Sciences (CAS) synthesized a double bond containing itaconic acid based epoxy resin (EIA). This epoxy resin showed low viscosity, high epoxy value (>0.62), as well as simple synthesis process and low cost. Compared with DGEBA, this epoxy resin exhibited comparable or better properties after curing with the same curing agent, and its properties could be further regulated due to the double bond. Thus this epoxy resin has a great potential utilization. The results have been published in Green Chemistry (IF=6.82) (Green Chem., 2013, 15, 245–254, Full Paper) and meanwhile, three Chinese patents (201110245232.X, 201210196485.7, 201210196521.X) have been filed, and one of them has been authorized.

Considering the double bond of itaconic acid and the low flame retardancy of epoxy resins, Prof. Zhu’s group chemically incorporated a fire-resistant DOPO into the itaconic acid based epoxy resin and got a phosphorus-containing itaconic acid based epoxy resin (EADI). As a matrix, its cured epoxy network showed comparable glass transition temperature and mechanical properties to diglycidyl ether of bisphenol A (DGEBA) system as well as excellent flame retardancy with UL94 V-0 grade during vertical burning test. As a reactive flame retardant, it showed good flame-resistant effect on DGEBA/ MHHPA system. EADI has shown great potential to be used as a green candidate for fire-resistant applications in some fields. Up to now, two Chinese invention patents have been filed about this epoxy resin (201310035530.5, 201310034348.8).

EIA was a mixture of different oligomers,and its remaining double bond was used during the curing process. Prof. Zhu’s group planned to make the best use of the carboxyl groups and double bond of itaconic acid during the synthetic process and designed a trifunctional epoxy monomer (TEIA) which showed high epoxy value (1.16) and low viscosity (0.92 Pa s, 25 oC). Due to the high epoxy value, its properties could be manipulated and high-performance materials could be obtained by selecting different curing agents. Due to the low viscosity, TEIA systems had better processability than DGEBA systems. The results has been published in Chemsuschem (IF=7.475) (ChemSusChem, 2013, 10.1002/cssc.201300749, Full Paper) and a Chinese invention patent has been fllied (201310042243.7).

|

|

The chemical structures of itaconic acid, EIA, EADI and TEIA

|

Prof. Jin Zhu jzhu@nimte.ac.cn

Research Group url: http://english.nimte.cas.cn/rh/rd/bp

All Iamges by