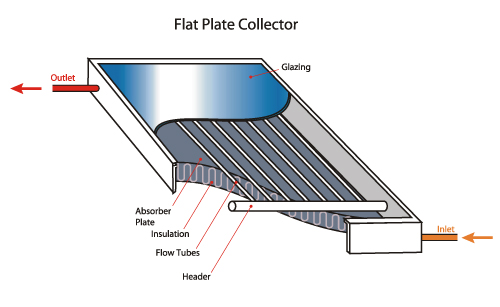

Currently, with the world wide exhaustion of fossil fuel and environment pollution,solar thermal systems have attracted ever-increasing attentions, since they can offer a pathway to a cost-competitive alternative to our traditional energy harvesting. Inside the solar thermal system (Fig. 1), the solar selective absorber coating is one of the key components (Fig. 1), which enables solar photo-thermal converting.

In theory, this coating is capable of harvesting a high proportion of the solar radiation into heat,simultaneously reducing the emission of heat, i.e., it possesses high solar absorptivity (α) in the wavelength range of 0.3-2.5 μm and low thermal emissivity (ε) in the infrared region of 2.0-20 μm. The ratio of α to ε, so-called solar selectivity, is used to evaluate the spectral selectivity of solar selective absorber coatings.

Numerous attempts are concentrated on how to boost the optical properties of absorber coatings. However, there is a continuous need to increase the thermal stability of the coating, in order to reduce the performance degradation to a minimum in the whole lifetime of the solar thermal system.

|

|

|

Figure 1. Upper one: Schematic of the flat plate collector, in which the absorber plate is the key component; Bottom one: The flat plate collector used in the domestic hot water supply. |

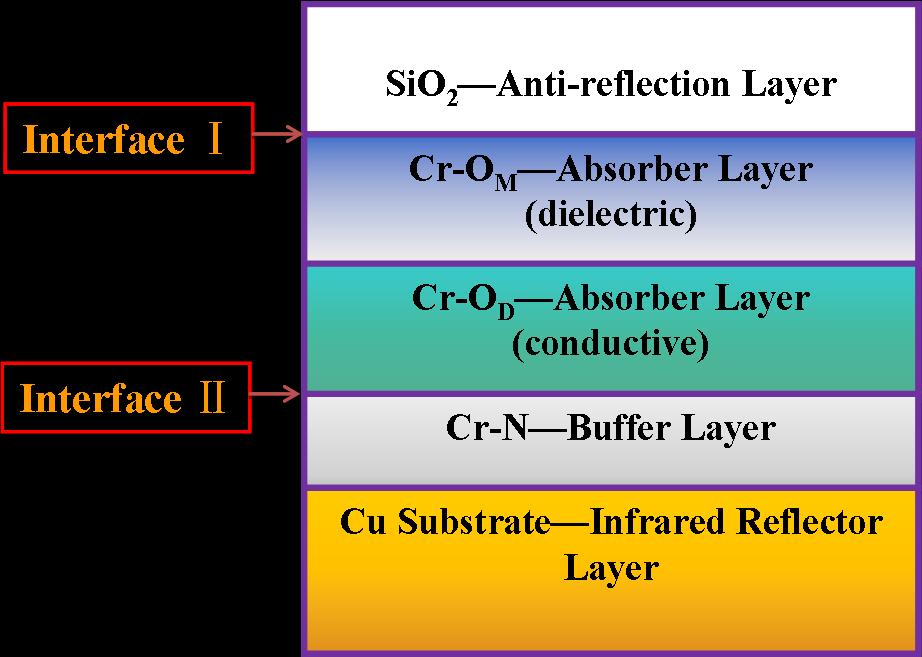

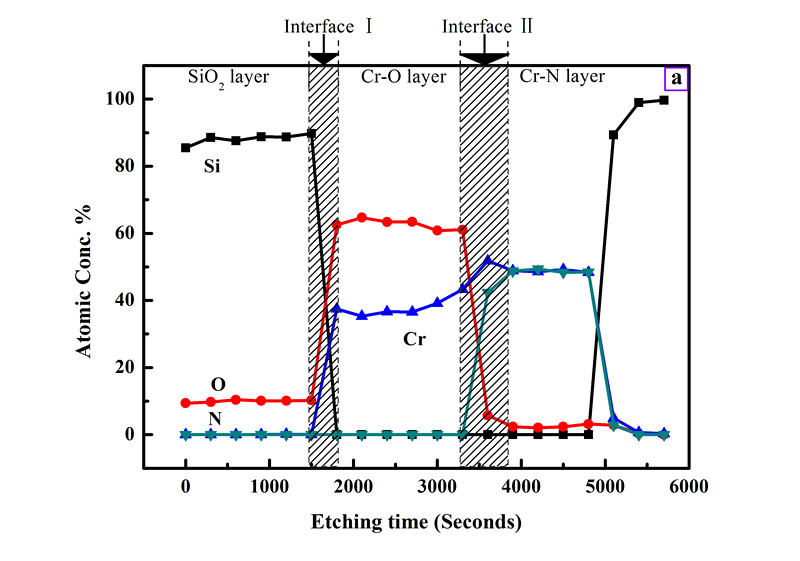

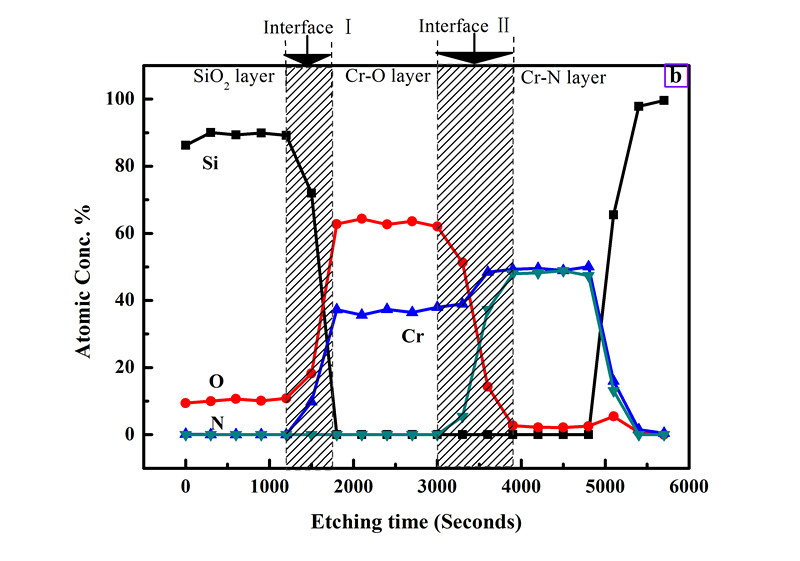

Recently, the research team led by Dr. Hongtao Cao, has developed Chromic-based absorber coatings. Then the related thermal aging mechanisms have been proposed. The CrNxOy coatings were prepared on Cu or Si substrates (Si substrate as a reference) using a DC reactive magnetron sputtering system with a 2 inch Cr metallic target (99.95%). In the multilayer structure design, the layer of the Cr-N, Cr-O, and SiO2 was selected and deposited as the diffusion barrier, absorber layer, and anti-reflection layer, respectively. Moreover, the Cu substrate can be used as the infrared reflective coating (Fig. 2). Under the condition of process optimization, the coating exhibits a high absorptivity (α) of 0.947 and a low emissivity (ε) of 0.05 at 80℃. Then, the dependence of optical properties, microstructure, and chemical composition of the coatings before and after thermal treatment was investigated by Micro-Raman spectroscopy, X-ray photoelectron spectroscopy, and Auger electron spectroscopy, in order to probe the correlation between the performance degradation and aging mechanisms. It was revealed that the copper diffusion whether throughout the entire stacked layers or near the interface region, the chemical interactions adjacent to the interface, and the interface width broadening (Fig. 3) are the Achilles’ heel for the solar thermal coatings to sustain high thermal stability.

|

|

Figure 2. Schematic diagram of Cu/CrOxNy/SiO2 absorber coating. |

|

|

|

Figure 3. AES analysis results of the Si/CrNxOy/SiO2 coating: (a) as-deposited; (b) 278 ℃ treated for 300h. |

This work has been published on Soar Energy Materials & Solar Cells, 114, 186(2013).

Professor Hongtao Cao h_cao@nimte.ac.cn

Research Group Url: http://english.nimte.cas.cn/rh/rd/mstffd/

All Images by