Ultra high molecular weight polyethylene (UHMWPE), is a linear high-density poly (ethylene) with a molecular mass in the range of 2×106 to 16×106 Dalton, whose extremely high molecular mass provides it with exceptional impact strength, low coefficient of friction and self-lubricating properties, excellent dielectric properties, and high anti-corrosive performance. However, the surface of UHMWPE is chemically inert and of low surface energy for lacking of reactive groups but full of non-polar -CH2- groups, which makes it incompatible with other materials and narrows its real application.

Recently, the functional organic coating team, led by Prof. Xuedong Wu, from the Ningbo Institute of Materials Technology & Engineering (NIMTE), Chinese Academy of Sciences (CAS), made progress in the area of UHMWPE surface modification. The surface-active fibers and powers of UHMWPE are expected to be utilized in the conductive fibers with high-performance and anti-wear epoxy coating.

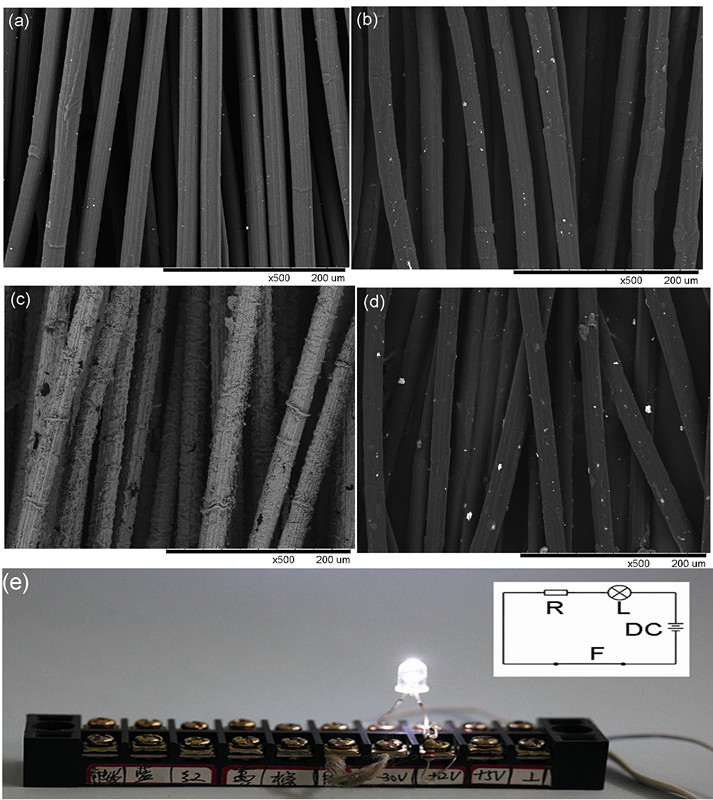

The researchers made use of the special property of dopamine to activate the surfaces of UHMWPE fibers. The method of electroless silver plating is utilized to metallize the surfaces of UHMWPE fibers. Therefore, the conductive UHMWPE fibers with high electric conductivity are fabricated via a mussel-inspired deposition. The silver-coated UHMWPE fibers with excellent conductive property are fabricated by the method of electroless silver plating with the assistance of dopamine. The resistance of the silver-coated fibers can be as low as 0.15 Ω/cm per bundle, which might lead to a promising application in the field of conductive polymer fabrics. Furthermore, these conductive fibers are propitious to apply in harsh environment condition due to their excellent mechanical and chemical properties of UHMWPE fibers. This work was recently published on the Journal of Applied Polymer Science (DOI: 10.1002/app.38228).

|

|

Fig.1. SEM micrographs of (a) original fibers, (b) dopamine-activated fibers, (c) silver-coated fibers, and (d) silver-coated fibers without dopamine activation; (e) conductive UHMWPE fibers (F) installed in a simple series circuit with a flash lamp (L), a resistance (R, 100 X), and a DC power supply (DC, 8.5 V). As turning on the DC power supply, the flash lamp gives out bright light. |

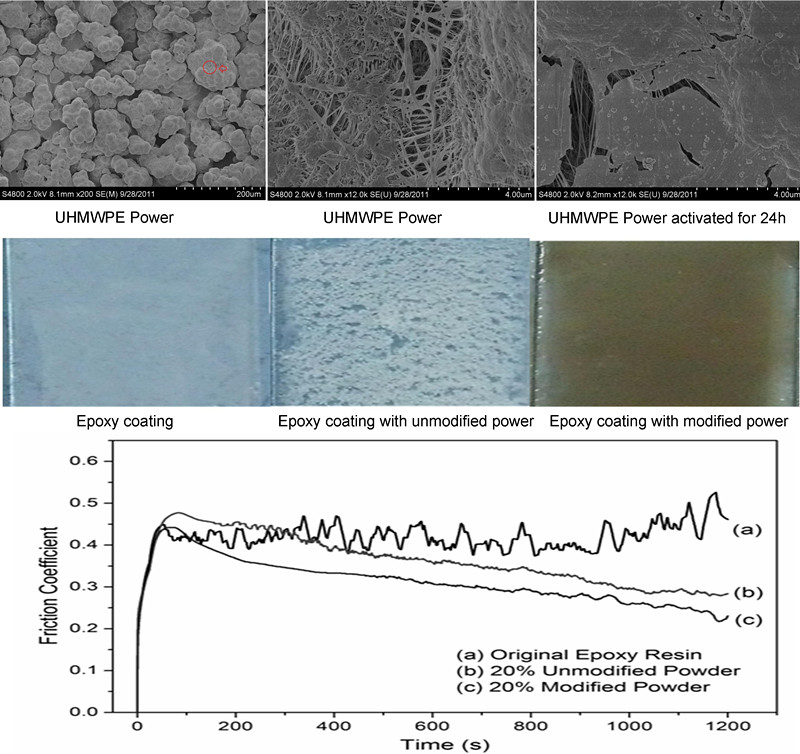

The dopamine-modified UHMWPE powders became more compatible in the epoxy resin and they could react with the epoxy molecule which made the powers hard to be peeled off by curing in the epoxy coatings. Then epoxy coatings with excellent anti-wear and tough properties are prepared. The impact-resistance performance of epoxy coating is enhanced by increasing the dopamine-modified powder content. In addition, friction coefficient and wear rate are also decreased. The comprehensive performance of epoxy coating with dopamine-modified powders is better than the one with unmodified powders. Related results were published on the Journal of Tribology, 32 (2012) 435-443.

|

|

Fig.2. Surface morphology and tribological properties of original epoxy coating, epoxy coating with unmodified powder and modified power. |

The adhesion strength between UHMWPE and other materials is enhanced greatly via surface modification. UHMWPE will be widely used as marine materials in the future due to its high toughness, excellent corrosive resistance and strong anti-wear ability.

There are also two patents that have been filed (CN201110175021.3, CN201110158646.9) based on this work, and to date one of them (CN201110158646.9) is granted.

Professor Xuedong Wu xdwu@nimte.ac.cn

Research Staff url: http://english.nimte.cas.cn/pe/fas/200909/t20090929_44484.html

All Images by