LED is a solid-state semiconductor device which can convert electrical energy into visible light. It has many advantages, such as small size, low power consumption, long service life, high brightness, low heat, environmental protection, durability, multi-variations and so on. Therefore, it is called the pride of green lighting in the 21st century. LED lamp will become the new lighting source following the incandescent and fluorescent lamps. Especially in landscape lighting, LED lamps have some advantages, such as low-voltage power supply, high reliability, good controllability, fast response time, repeating frequently on and off and good flexibility, which can meet the decorative lighting requirements with various geometric dimensions and different spaces.

Radiator is an important component of the LED lamp and can distribute the internal heat more easily to the external environment, which improves the efficiency of transformation of electric energy into light energy. At present, the most common LED lamp radiator is aluminum alloy extrusion or die casting molding. However, it has some shortcomings, such as big density, high cost of post processing, low efficiency and so on, which limit the application in high-power LED lamp. Compared with the aluminum alloy material, the high thermal conductivity resin matrix composites have some advantages, such as light weight, low cost, easy processing, forming complex shape and recycling, which become an important direction on the research and application of LED thermal conductivity material.

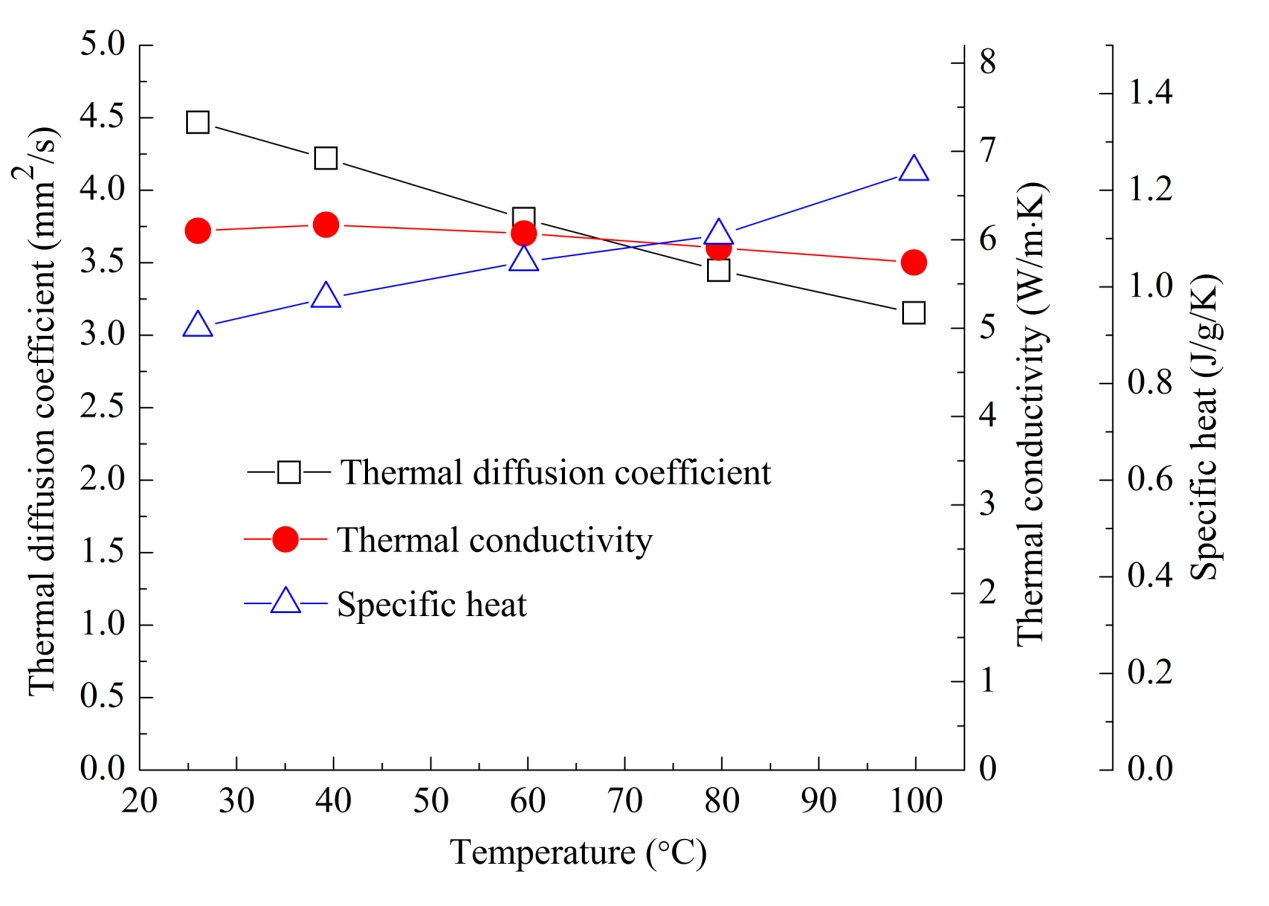

At present, composite materials research team of the Ningbo Institute of Materials Technology &Engineering, CAS achieves a research progressin the high thermal conductivity of thermoplastic matrix composites. The high thermal conductivity composites of nylon 6 resin matrix were developed by the twin-screw extruder. Figure 1 shows the sample of granular material. The density of thehigh thermal conductivity composites of nylon 6 resin matrix is 1.504g/cm3 (20°C), much lower than that of the aluminum alloy (2.7g/cm3), which can meet the weight requirements of high-power LED radiator ( such as 7W high power LED lamp, its weight of radiator is less than 85g). The results from Figure 2 show that the thermal conductivity of composites reaches 6.101W/m×K at 25°C, which is 25 times of the pure nylon 6 resin’s thermal conductivity (0.243 W/m×K). The thermal conductivity of composites is 5.910 W/m×K at 80 °C.

|

|

Figure 1 The extrusion material sample photo ofhigh thermal conductivity composites (Image by NIMTE) |

LED radiator is prepared with the high thermal conductivity thermoplastic matrix composites and designed by optimization of thermal management, which can meet the performance requirements of lightweight and high thermal conductivity. In addition, the low cost nylon 6 resin matrix composites can be extruded continuously by the extruder and recycled. Welcome the domestic and foreign enterprisers to contact with us to develop the lightweight LED lamp radiator with high thermal conductivity or other similar products.

|

|

Figure 2 The thermal conductivity of high thermal conductivity composites (Image by NIMTE) |