The performance of carbon fiber-reinforced composites is dependent to a great extent on the properties of fiber-matrix interface. Good interfacial properties are essential to ensure high-performance of carbon fiber composites used in aerospace and automotive industries. Developing novel methods to improve the strength of carbon fiber-matrix interface is an important direction for fiber-reinforced composites research area.

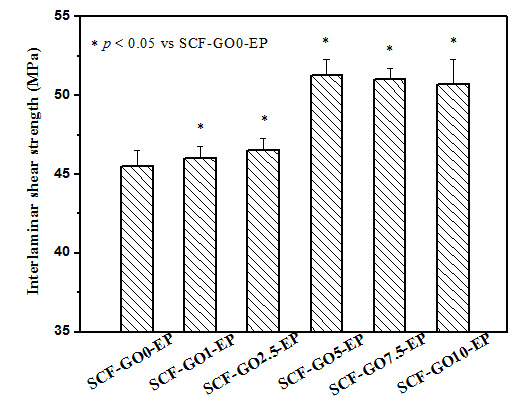

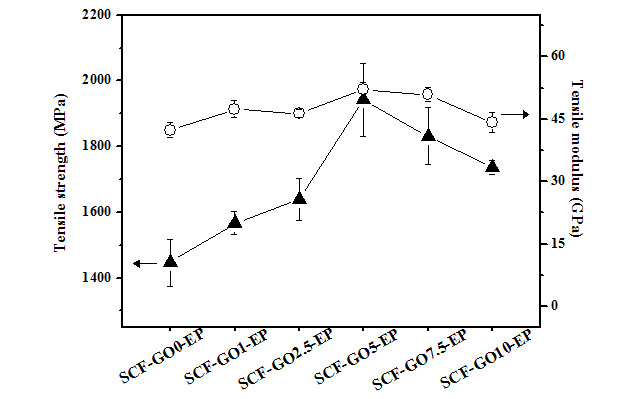

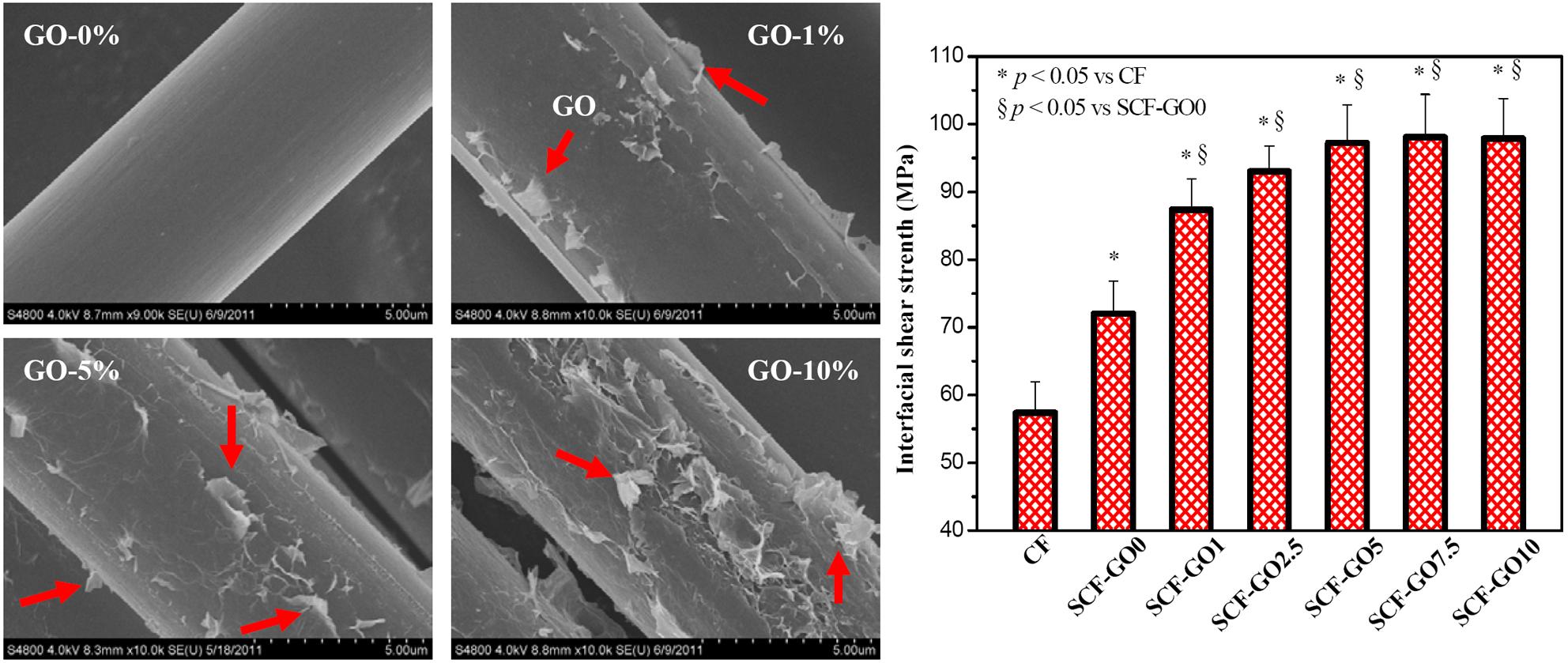

The research group in the Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, has developed an innovative and convenient method for improving carbon fiber composites interfacial properties by means of directly introducing graphene oxide (GO) sheets dispersed in the fiber sizing onto the surfaces of individual carbon fibers. The microstructure of carbon fiber interface can be rationally controlled by adjusting the GO loadings (Figure1). The homogeneously dispersed GO sheets surrounding the carbon fibers, have obviously enhanced the interfacial shear strength (IFSS) of composites with 70.9% and 36.3% improvement compared with that of the virgin carbon fiber composites with commercial sizing (Figure1). Furthermore, the improvement of interlaminar shear strength and tensile properties of GO modified carbon fiber composites has also been observed in the mechanical test results (Figure 2).

Figure 1. Scanning electron microscopy of the carbon fibers after thermal defunctionalization (800oC, N2) and interfacial shear strength (IFSS) results of single carbon fiber composites |

|

Figure 2. (A) Interlaminar shear strength (ILSS) of unidirectional carbon/epoxy composites; (B) Tensile properties of unidirectional carbon fiber/epoxy composites tested in the fiber direction:Tensile strength (▲) and Elastic modulus (○). |

Prof. Xinyu Fan xinyu.fan@nimte.ac.cn Research Group Url: http://english.nimte.cas.cn/rh/rd/cme/