Mullite Fiber is one kind of high-tech structural materials that are especially for high temperature application. With its excellent mechanical and low thermal conductivity properties, mullite fibers have been widely used as thermal insulator materials in industries of steel, non-ferrous metal, construction materials, energy saving and new-tech industries. Thus, mullite fiber plays a key role in the national economy development and is an important element to improve industries’ energy efficiency.

One of the most important challenges in manufacture of mullite fiber is to control the porosity which may lead to fracture and low strength of fibers. In order to solve the problem, structural and functional integration ceramics group led by Professor Qing Huang of NIMTE has been collaborating with Zhejiang Osmun Crystal Fiber Ltd. to improve the quality of mullite fiber since November 2011.

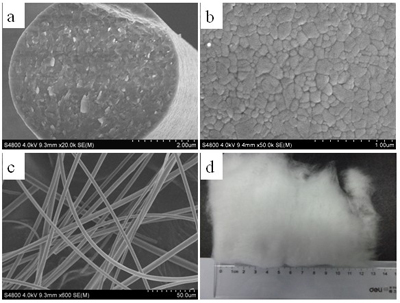

At present, the group has made a progress to reduce the porosity and improve the strength of mullite fiber after research lasting for almost 6 months. The researchers applied microwave heating method to produce mullite fiber at a lowered temperature and shortened synthesis time, and improved production efficiency, reduced the production cost.

All experiments were carried out on the industry facilities. The success in the fabrication of high-quality mullite fiber lays a strong foundation on the further research of composite materials.

Professor Qing Huang huangqing@nimte.ac.cn

Research Group Url: http://english.nimte.cas.cn/rh/rd/sfioc/