Nowadays, water resource shortage and water pollution are becoming more and more serious. Water-treatment technology based on membranes has been widely applied in waste water, drinking water and pharmacy purification fields due to its high efficiency, low cost, environmental friendly, constant temperature operation, and non-chemical reaction etc. Poly(vinylidene fluoride) (PVDF) is a popular membrane material due to its excellent chemical resistance, thermal stability and mechanical property and has been used in municipal waste water, industrial waste water, the upgrading of drinking water plant, and pretreatment of sea water desalination. However, commercial PVDF membranes tend to have low water flux and also high organic matter fouling potential due to its high surface hydrophobicity. Therefore, how to improve the permanent hydrophilicidy is of great interest to academic and industrial communities.

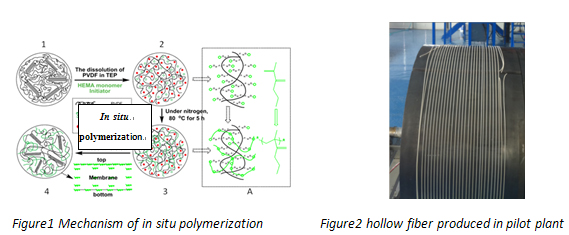

The functional membrane research group in Ningbo Institute of Materials Technology & Engineering (NIMTE) led by Professor L. Luke Xue and Dr. Fu Liu has developed the new super hydrophilic PVDF dry membranes through a Nat-ips and in situ polymerization technique, which can tune and control the dispersion and surface segregation of hydrophilic polymer chains precisely. The contact angle of prepared membrane decreased from 60 degree to 0 in less than 30 seconds. The pure water flux is 165LMH with excellent fouling resistant. The special advantage of this technique is that high rejection and high flux can be obtained without the addition of extra pore formers. The excellent reversible wettabilty of the membranes makes the dry storage and transportation of the membranes possible, which can effectively avoid the contamination of bacterial, and reduce the cost from storage and transportation.

Above research work was published in Journal of Material Chemistry (Impact factor 5.099, 2012,22,9131-9137) under British Royal Society of Chemistry. Hydrophilic microfiltration membranes with flux up to 2000LMH were also prepared through this technique. In a combined continuous hollow fiber membrane manufacturing pilot process, in situ polymerization were used to improve the stability of the hydrophilicity, while Nat-ips method was used to produce inter-connected pores, and inner-support matrices were used to render high mechanical strength. Hydrophilic hollow fiber membranes with ultra-high strength and high flux, and high performance water treatment modules from the membranes have been produced in pilot plant scale.

Images by NIMTE

Professor L. Luke Xue, xuelx@nimte.ac.cn

Research Group homepage http://english.nimte.cas.cn/rh/rd/fpm