Researchers at the Division of Functional Materials and Nanodevices, the Ningbo Institute of Materials Technology &. Engineering (NIMTE) have deloped a simple and viable route to produce various oxide micro/nano particles in kilogram quantities with low cost, simple and controllable process. According the route, the monodisperse micro/nano particles such as Silica, Titania, Hematite and Zinc Oxide were synthesized successfully.

|

|

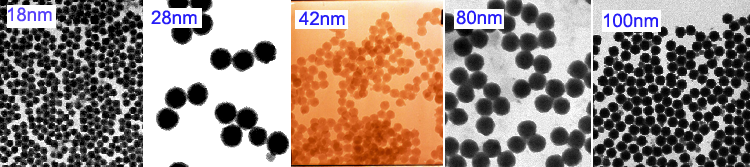

Pic1. Mass Products (Image by NIMTE) |

The nanoparticles, including powders and colloids, may exhibit novel properties relative to fine particles and bulk materials due to increased percentage of atoms at the surface of a nanoparticle. Thus, they have a wide variety of potential applications in biomedical, optical, magnetic/electronic and catalysis fields. The unique properties of nanoparticles depend decisively on their size, shape and structure, and thus development of low-cost, simple and controllable processes is intensive studied issues of nanoscience. However, most of monodispersed particles are still prepared in exceedingly dilute system due to the problem of coalescence. The synthesis and applications of these materials are still in an early stage of technical development on account of the limited approach to produce diverse materials with controllable structure and properties.

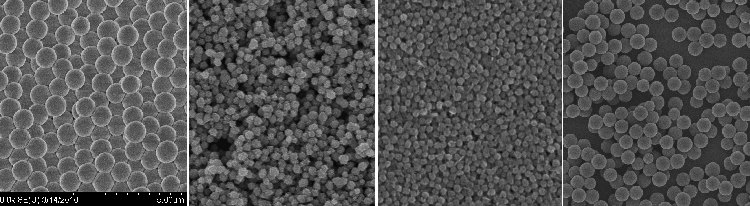

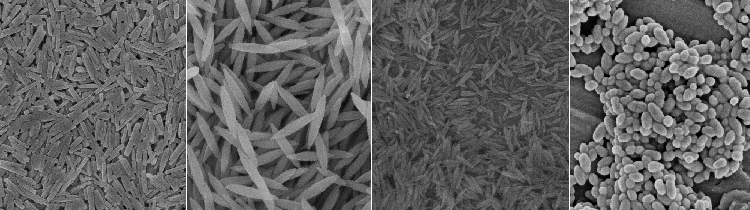

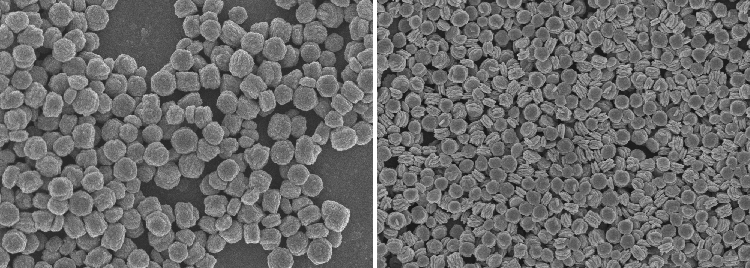

The researchers systematically studied the characteristic and common formation law of typical monodispersed metal oxide nanoparticles, developed a simple, scalable and high yield approach for the production of various monodispersed micro/nano particles with controllable size, shape and property by using of the most inexpensive precursors. More remarkably, the monodispered spherical silica colloid with different sizes (8~100 nm) can be prepared by a phase-transfer method in large scale. The polydispersibility is less than 10%. Further, the kilogram scale productions of spherical titania, cigar-shaped hematite and columnar zinc oxide, with size range form 200 to 2000 nm and polydispersity less than 15%, can also be achieved by simple one-step precipitation method. This will promote the applications of these materials in electronic, smart fluids and special coatings.

Pic.2 Mass-produced Silica Sol (Image by NIMTE)

Pic3. Mass-produced Titania (Image by NIMTE)

|

| Pic4. Mass-produced Hematite (Image by NIMTE) |

|

| Pic5. Mass-produced Zinc Oxide (Image by NIMTE) |

Contacts Prof. Xu Gaojie xugj@nimte.ac.cn