White pollution is becoming a serious environmental issue in the world, which is mainly due to the wide use of polystyrene (PS) foamed products. However, the growth of PS foam usage continues to be strong, especially in Asia, around half the world total, major use for protective packaging. The main reasons are low price, reasonable properties and mature processing technology. In the past few years, several developed countries have promulgated decrees to prevent the usage and forced the manufacturer to recycle their waste products, but the problem seemed not to be solved efficiently,

|

| Figure 1. Optical photo of PLA bead foam |

Poly(lactic acid) (PLA) is a biodegradable polymer, produced from renewable natural resources. PLA exhibits a glass transition temperature in the range of 50-60°C. Below the temperature, PLA is rigid and brittle. Increasing the crystallinity of PLA tends to increase the tensile modulus and strength as well as the service temperature of PLA. Unfortunately, the crystallization of regular PLA occurs too slowly to develop significant crystallinity. Therefore, how to enhance crystallization behavior and increase crystallinity of PLA has been widely discussed in the research on PLA processing. Researchers have found that the microcellular foaming could contribute to the crystallinity increase of PLA, however, the preparation of well-defined PLA foams and the development of PLA foaming technology are still very challenging.

|

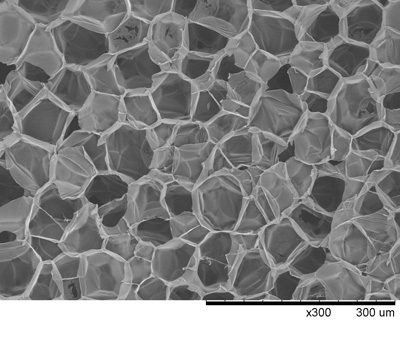

| Figure 2. Cell morphology of PLA bead foam |

Contacts Dr. Wentao Zhai (wtzhai@nimte.ac.cn) and Dr. Wenge Zheng (wgzheng@nimte.ac.cn)