Generally, the high-performance permanent magnet means a magnet with a high energy product, high coercivity, and high work temperature. The group of PMs & Application of the Ningbo Institute of Material Technology and Engineering (NIMTE),CAS has dedicated to the research and development of industrial technology for high-performance neodymium magnet, and made a series technological progress at production process.

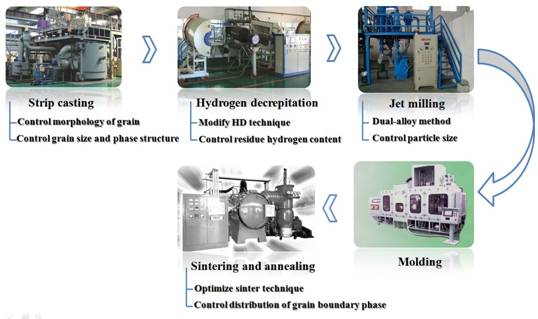

For preparation of the excellent performance of NdFeB magnets, technologic processes of preparation, including strip casting, hydrogen decrepitation, jet milling, etc., are optimized in details. Researchers make a systematic study on the mechanism of grain growth, and obtain the developed strips with uniform columnar grain structure. This technique progress has reached the international advanced level. Furthermore, the effects of the residue hydrogen content on the magnetic properties and corrosion resistance of Nd-Fe-B sintered magnets are studied. The sintering processes of magnets with different residue hydrogen contents are studied systematically, and it was found that high residual hydrogen contents can result in local HDDR and a decrease in magnetic properties of magnets. Base on this research results, the improved HD technique is presented. In addition, the preparations of low temperature coefficient magnets have a significant progress. The primary and secondary alloy were designed and blended with rational allocation by dual-alloy method and process optimization. The absolute value of temperature coefficient of coercivity reaches 0.53%/℃, much lower than that of magnets (0.64 %/℃) prepared by single alloy with same alloy composition.

All above research results have been presented at the 55th Annual Conference on Magnetism and Magnetic Materials (Nov. 14-18, 2010 Atlanta, GA), and garnered much attention from international researchers. (Reported by Guo Shuai)

(image by NIMTE)